What is Precision Machining?

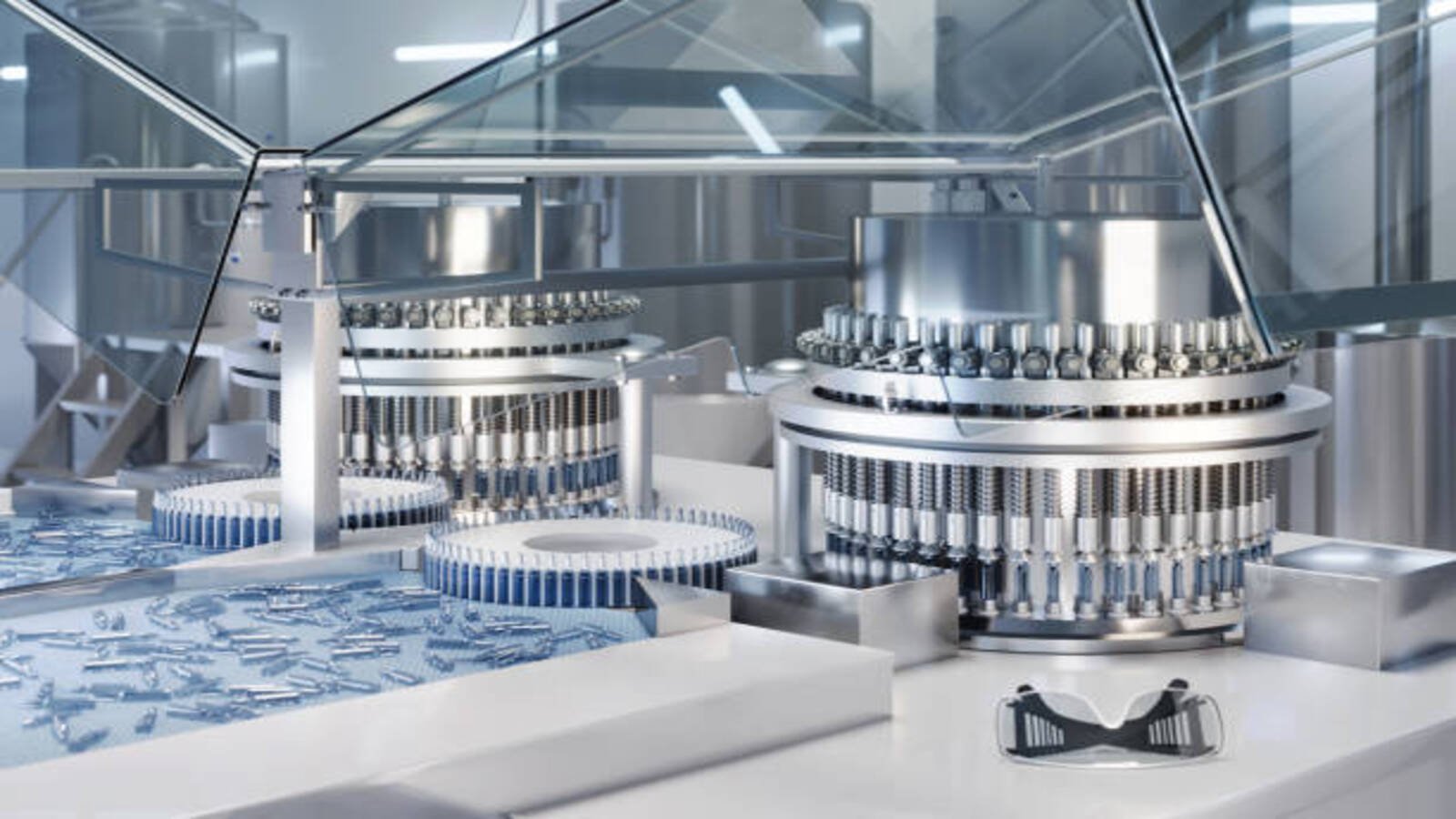

Precision machining is a process that involves the creation of intricate metal parts that meet precise measurements and specifications. This process involves the use of specialized machinery, tools, and software to produce high-quality parts. Precision machining is essential for manufacturing industries that require small, complex, or unique parts.

Types of Precision Machining

There are several types of precision machining, including milling, turning, drilling, grinding, and honing. Each type of machining requires different tools and techniques to achieve precise measurements and specifications. The process of precision machining involves many steps, such as planning, design, programming, setup, testing, and production.

The Benefits of Precision Machining

Precision machining offers many benefits for metal parts manufacturing. These benefits include increased efficiency, reduced waste, improved quality control, and faster production times. Precision machining also allows manufacturers to create unique, complex, or customized parts that cannot be produced by other manufacturing methods.

The Role of Technology in Precision Machining

Technology plays a crucial role in precision machining. The use of computer-aided design (CAD) software and tools allows manufacturers to create complex designs and models that are precise and accurate. Precision machining also involves the use of computer numerical control (CNC) machines that use programmed instructions to control the manufacturing process.

The Importance of Quality Control in Precision Machining

Quality control is essential in precision machining to ensure that parts meet precise measurements and specifications. Manufacturers use a variety of inspection methods, such as visual inspection, coordinate measuring machines (CMMs), and microscopes, to ensure that parts are accurate and precise.

The Applications of Precision Machining

Precision machining has many applications in different industries, including aerospace, automotive, medical, and military. Precision machining is used to create complex parts, components, and systems that are essential for these industries.

The Future of Precision Machining

The future of precision machining looks promising, with advancements in technology that will improve efficiency, accuracy, and quality control. The use of automation, robotics, and artificial intelligence (AI) will revolutionize the precision machining industry, making it faster, more efficient, and more accurate.

The Importance of Choosing a Reliable Precision Machining Company

Choosing a reliable precision machining company is essential for metal parts manufacturing. A reliable company will have the expertise, experience, and equipment necessary to produce high-quality parts that meet precise measurements and specifications. A reliable company will also have a strong focus on quality control and customer satisfaction.

The Cost of Precision Machining

Precision machining can be costly, but it offers many benefits for metal parts manufacturing. The cost of precision machining depends on several factors, such as the complexity of the part, the type of machining required, and the quantity of parts needed. However, the benefits of precision machining, such as increased efficiency, reduced waste, and improved quality control, can outweigh the cost.

The Importance of Communication in Precision Machining

Effective communication is crucial in precision machining to ensure that parts meet precise measurements and specifications. Communication between the manufacturer and the customer is essential to ensure that requirements are being met and issues are being addressed. Clear, concise, and open communication is necessary for successful precision machining.

Quote Inquiry

Contact us!