Overview of Copper and Aluminum Components Manufacturing

Copper and aluminum components manufacturing for electrical transformers plays a crucial role in the production of high-quality, efficient transformers. These components are essential for the seamless operation and reliability of transformers in various industries.

Benefits of Using Copper and Aluminum Components

Copper and aluminum components are preferred materials for manufacturing electrical transformers due to their excellent conductive properties. Copper is known for its high conductivity and thermal stability, while aluminum is lightweight and cost-effective. Both materials are essential for ensuring the optimal performance of transformers.

Quality Assurance in Manufacturing Process

The manufacturing process of copper and aluminum components for electrical transformers requires strict adherence to quality standards. Quality assurance measures are implemented to ensure that the components meet the required specifications and perform reliably under various operating conditions.

Cost-Effectiveness of Copper and Aluminum Components

Despite the initial cost of copper and aluminum components, their long-term cost-effectiveness makes them a popular choice for transformer manufacturers. These materials offer durability, reliability, and efficiency, resulting in lower maintenance and operating costs over the transformer's lifespan.

Customization Options for Transformers

Manufacturers of copper and aluminum components for electrical transformers offer customization options to meet the specific requirements of their clients. Custom-designed components can enhance the performance and efficiency of transformers in different applications and environments.

Environmental Sustainability in Manufacturing

The production of copper and aluminum components for electrical transformers focuses on environmental sustainability. Manufacturers use eco-friendly practices and materials to minimize the impact on the environment and reduce carbon footprint during the manufacturing process.

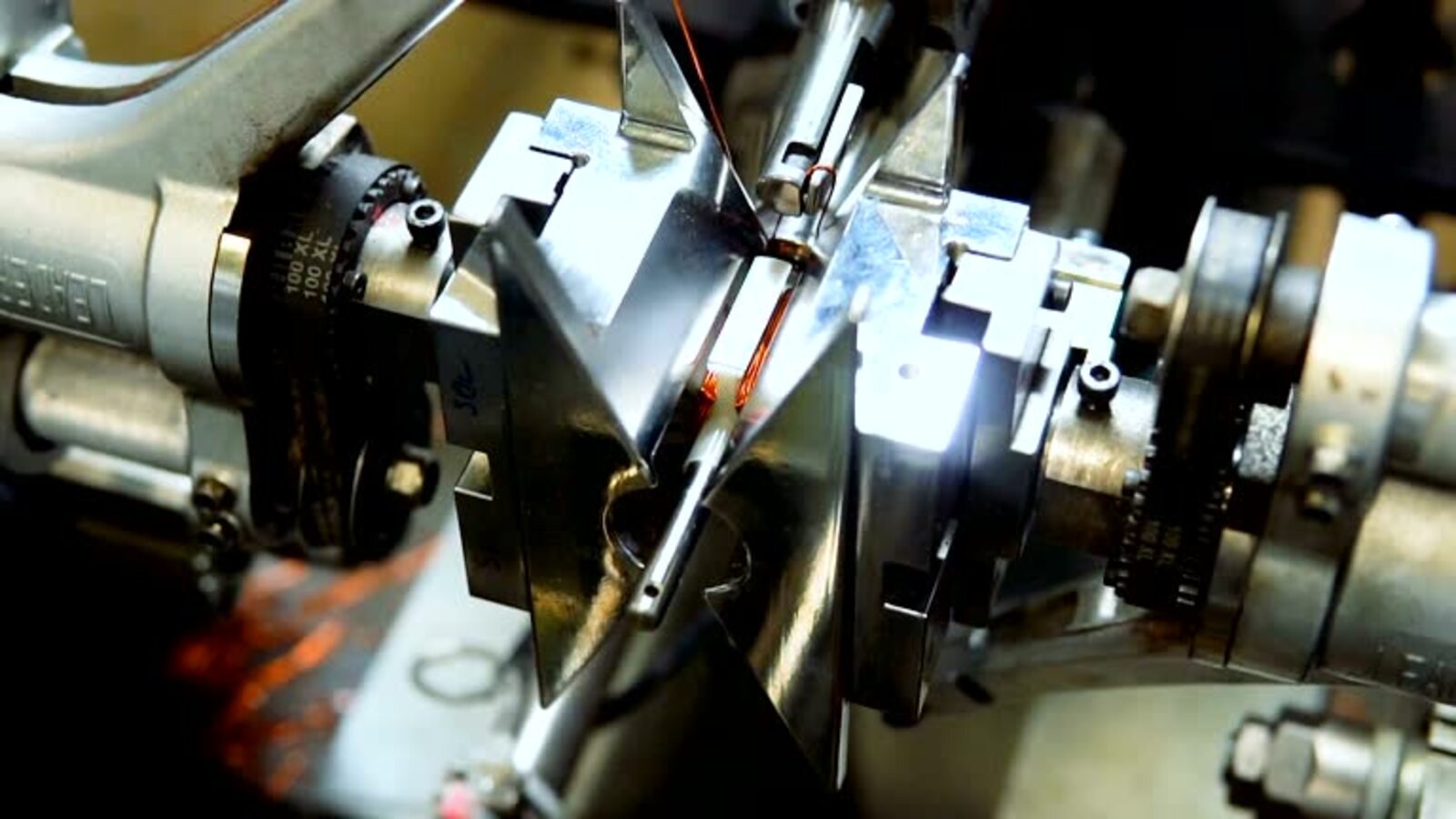

Technological Innovations in Component Manufacturing

Advancements in technology have revolutionized the manufacturing of copper and aluminum components for electrical transformers. High-tech equipment and processes enable manufacturers to produce components with precision, efficiency, and reliability, meeting the demands of modern transformers.

Testing and Certification of Components

Before being integrated into transformers, copper and aluminum components undergo rigorous testing and certification procedures. Quality control measures ensure that the components meet industry standards and specifications, guaranteeing the performance and safety of the transformers.

Supply Chain Management in Component Manufacturing

Effective supply chain management is essential in the manufacturing of copper and aluminum components for electrical transformers. Timely sourcing of materials, efficient production processes, and reliable distribution networks are critical factors in ensuring the seamless flow of components to transformer manufacturers.

Future Trends in Copper and Aluminum Component Manufacturing

The future of copper and aluminum components manufacturing for electrical transformers looks promising, with a focus on sustainability, innovation, and efficiency. Ongoing research and development efforts aim to improve the performance, durability, and cost-effectiveness of components, ensuring the continued advancement of transformer technology.

Quote Inquiry

Contact us!