1. Introduction

For any casting enthusiast, having the right tools and accessories is crucial to ensure the best casting results. One such essential item is a casting machine accessory. These accessories not only make the casting process smoother and more efficient but also improve the overall quality of the final product. In this article, we will explore the best casting machine accessories available in the market and discuss their features and benefits.

2. Crucible Tongs: Secure and Efficient Handling

Crucible tongs are a must-have accessory for any casting machine setup. These specialized tongs are designed to securely hold and maneuver crucibles, which are containers used to melt and pour metals during the casting process. The best crucible tongs are made of heat-resistant materials, such as stainless steel, to withstand high temperatures.

3. Graphite Stirring Rods: Aids in Mixing and Stirring

When working with molten metals, it is essential to have a reliable stirring tool to ensure proper mixing and homogeneity. Graphite stirring rods are the perfect accessory for this purpose. Their heat-resistant nature and excellent thermal conductivity make them ideal for handling molten metals, including gold, silver, and bronze.

4. Ingot Molds: Shape Your Castings with Precision

To create castings of specific shapes and sizes, ingot molds are indispensable accessories. These molds allow you to pour molten metal into predetermined shapes, resulting in accurate and consistent castings. The best ingot molds are made of durable materials like graphite or stainless steel, ensuring longevity and ease of use.

5. Safety Gear: Protect Yourself and Your Work

When working with casting machines and molten metals, safety should be a top priority. Investing in proper safety gear is essential to protect yourself from potential hazards. Safety accessories such as heat-resistant gloves, aprons, and face shields will provide the necessary protection and give you peace of mind during the casting process.

6. Casting Flux: Improve the Quality of Your Castings

Casting flux is a vital accessory that helps improve the quality of your castings. It is used to remove impurities and oxides from the surface of molten metals, resulting in cleaner and more flawless castings. Choosing the right casting flux, such as borax or boric acid, can significantly enhance the overall appearance and finish of your castings.

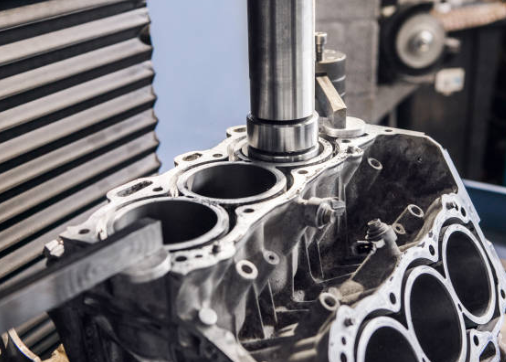

7. Melting Crucibles: Essential Containers for Melting Metals

When it comes to melting metals for casting, having the right crucible is crucial. Melting crucibles are specially designed containers that can withstand high temperatures and hold molten metals safely. They are available in various materials such as graphite, ceramic, and stainless steel. Choosing the appropriate crucible material depends on the type of metal being melted and personal preference.

8. Casting Ladles: Precise Pouring for Accurate Results

Accurate pouring of molten metal is essential for achieving desired casting results. A casting ladle is a tool specifically designed for this purpose. It allows controlled pouring and minimizes the risk of spillage or uneven distribution of metal. Look for ladles made of heat-resistant materials with comfortable handles for a steady and precise pouring experience.

9. Investment Powder: Ensuring Perfect Mold Creation

Investment powder, also known as casting investment, is a critical accessory for creating molds in the casting process. It is a fine powder that, when mixed with water, forms a moldable slurry. This slurry is used to create molds around wax patterns, which are then heated to create cavities for pouring molten metal. Choosing the right investment powder is vital for achieving precise and high-quality mold results.

10. Digital Temperature Controllers: Optimize Casting Conditions

Controlling and maintaining the temperature of molten metals is crucial for successful casting. Digital temperature controllers are accessories that help achieve precise temperature control during the melting and casting processes. These controllers allow you to set and monitor the temperature, ensuring consistent and accurate results every time.