High-Quality Materials for Reliable Performance

When it comes to manufacturing electrical components, the quality of the materials used is crucial. OEM copper and aluminum parts are known for their durability and conductivity, making them ideal choices for ensuring the reliability and performance of electronic devices.

Precision Manufacturing for Perfect Fit

OEM copper and aluminum parts are designed and manufactured with precision to ensure a perfect fit in electrical components. This level of accuracy helps to reduce the risk of malfunctions and ensures that the parts function seamlessly within the device.

Cost-Effective Solution for Manufacturers

Using

OEM copper and aluminum parts for electrical components manufacturing can be a cost-effective solution for manufacturers. These parts are often more affordable than custom-made options, allowing manufacturers to save on production costs without compromising on quality.

Compliance with Industry Standards

OEM copper and aluminum parts are manufactured to meet industry standards and specifications, ensuring that they comply with all regulatory requirements. This compliance is essential for manufacturers looking to maintain high standards of quality and safety in their products.

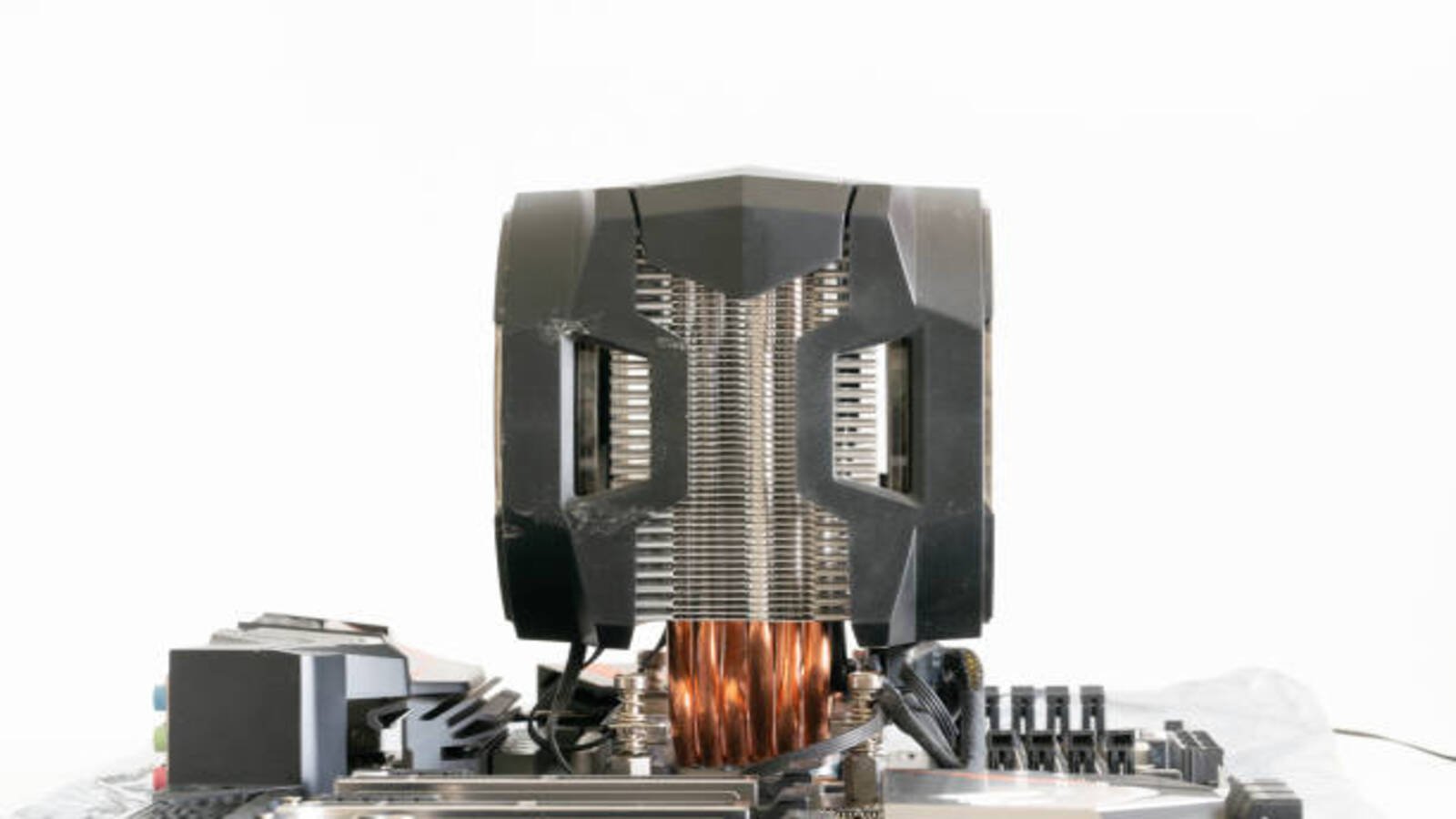

Enhanced Thermal Conductivity for Efficient Heat Dissipation

Copper and aluminum are known for their excellent thermal conductivity, which is important for electrical components that generate heat during operation. Using OEM copper and aluminum parts can help improve heat dissipation, leading to more efficient performance and longer lifespan of the device.

Customizable Options for Specific Requirements

Manufacturers may have specific requirements when it comes to the design and functionality of their electrical components. OEM copper and aluminum parts offer customizable options to meet these requirements, allowing manufacturers to create products that are tailored to their needs.

Long-Term Reliability for End Users

By using OEM copper and aluminum parts in the manufacturing of electrical components, manufacturers can ensure long-term reliability for end users. These high-quality materials are built to last, reducing the risk of premature failures and ensuring a positive user experience.

Compatibility with a Wide Range of Devices

OEM copper and aluminum parts are designed to be compatible with a wide range of electrical devices, making them versatile options for manufacturers. Whether it's for consumer electronics or industrial equipment, these parts can be seamlessly integrated into various products.

Environmentally Friendly Manufacturing Practices

Copper and aluminum are recyclable materials, making them environmentally friendly choices for manufacturing electrical components. By using OEM copper and aluminum parts, manufacturers can reduce their carbon footprint and contribute to sustainable practices in the industry.

Industry-Leading Expertise and Support

When choosing OEM copper and aluminum parts for electrical components manufacturing, manufacturers can benefit from the industry-leading expertise and support of trusted suppliers. These suppliers have the knowledge and resources to provide guidance and assistance throughout the production process.

Quote Inquiry

Contact us!