Efficiency in Electrical Panel Manufacturing

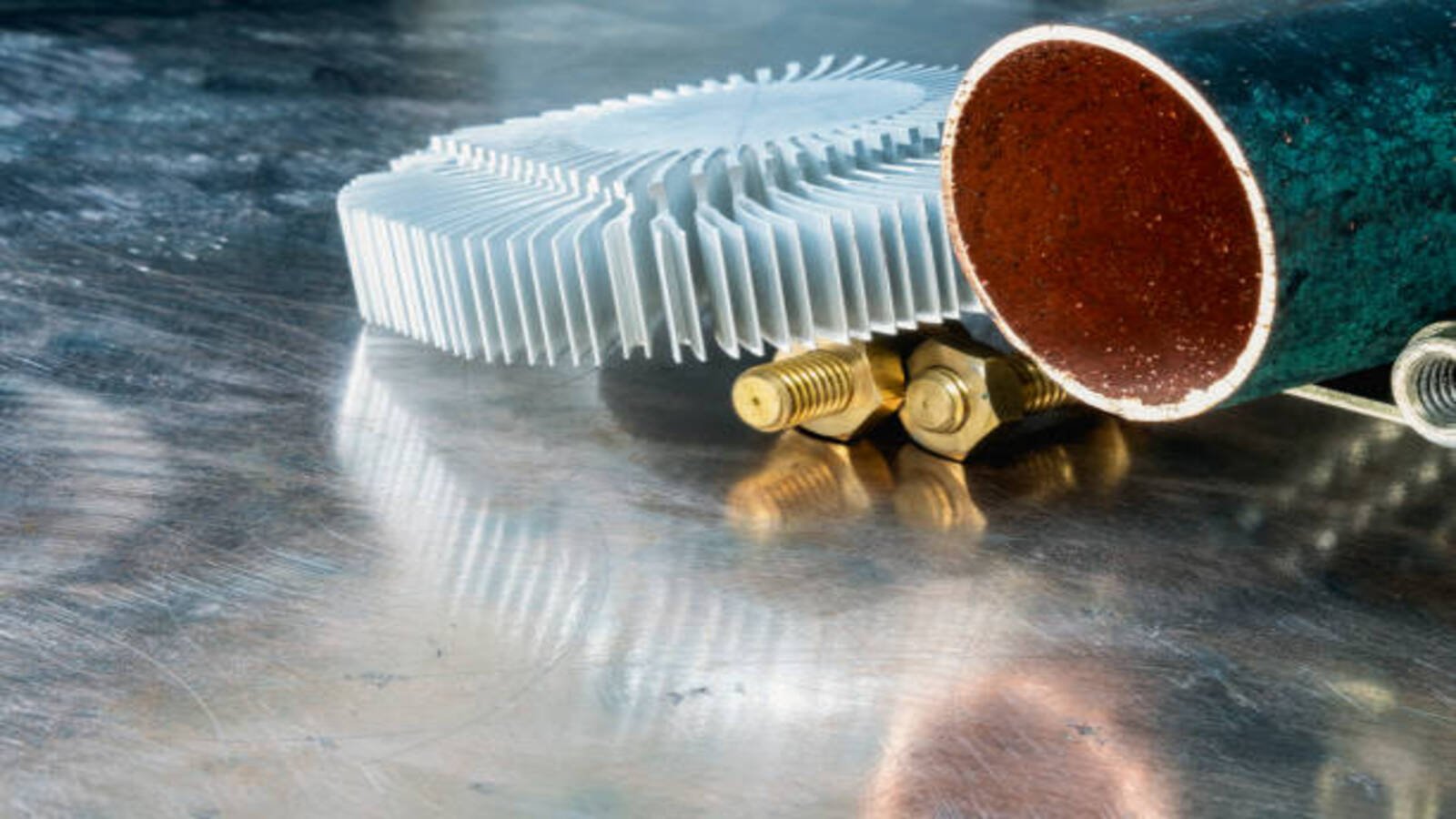

Custom machining of copper and aluminum parts for electrical panels allows for precise dimensions and specifications tailored to the exact needs of the application. This results in higher efficiency and effectiveness in the manufacturing process.

Material Selection and Compatibility

When it comes to electrical panels, the materials used are crucial for performance and safety. Custom machining ensures that the copper and aluminum parts are compatible with the specific requirements of the electrical panel, enhancing reliability and longevity.

Precision and Accuracy

Custom machining technology enables intricate designs and precise measurements to be achieved with ease. This level of precision is essential in the production of copper and aluminum parts for electrical panels, ensuring optimal functionality.

Quality Control and Assurance

With custom machining, thorough quality control measures can be implemented throughout the manufacturing process. This results in consistent quality and reliability of the copper and aluminum parts, meeting the highest industry standards.

Cost-Effectiveness and Value

While custom machining may require initial investment, it ultimately proves to be cost-effective in the long run. The tailored approach ensures that only the necessary materials are used, minimizing waste and maximizing value.

Customization for Unique Requirements

Every electrical panel may have specific requirements based on its intended use and environment. Custom machining allows for the customization of copper and aluminum parts to meet these unique needs, ensuring optimal performance.

Quick Turnaround Time

In today's fast-paced manufacturing industry, quick turnaround time is essential. Custom machining of copper and aluminum parts enables efficient production processes, reducing lead times and enhancing overall productivity.

Expertise and Experience

Partnering with a reputable custom machining service provider ensures access to a team of experts with extensive experience in working with copper and aluminum materials. This expertise guarantees the highest quality results for electrical panel components.

Innovation and Technology

Custom machining constantly evolves with advancements in technology. By utilizing the latest tools and techniques, manufacturers can achieve greater innovation and efficiency in producing copper and aluminum parts for electrical panels.

Sustainability and Environmental Responsibility

Custom machining prioritizes sustainability by promoting responsible material usage and waste management practices. By optimizing the production process for copper and aluminum parts, manufacturers can reduce environmental impact while maintaining product quality.

Quote Inquiry

Contact us!