The Importance of Switchgear Mechanical Parts Processing

Switchgear mechanical parts processing is an essential aspect of low-voltage switchgear systems. These systems are crucial for controlling, protecting, and isolating electrical equipment in various industries. Proper processing of switchgear mechanical parts ensures the reliability and safety of these systems.

Types of Mechanical Parts in Switchgear Systems

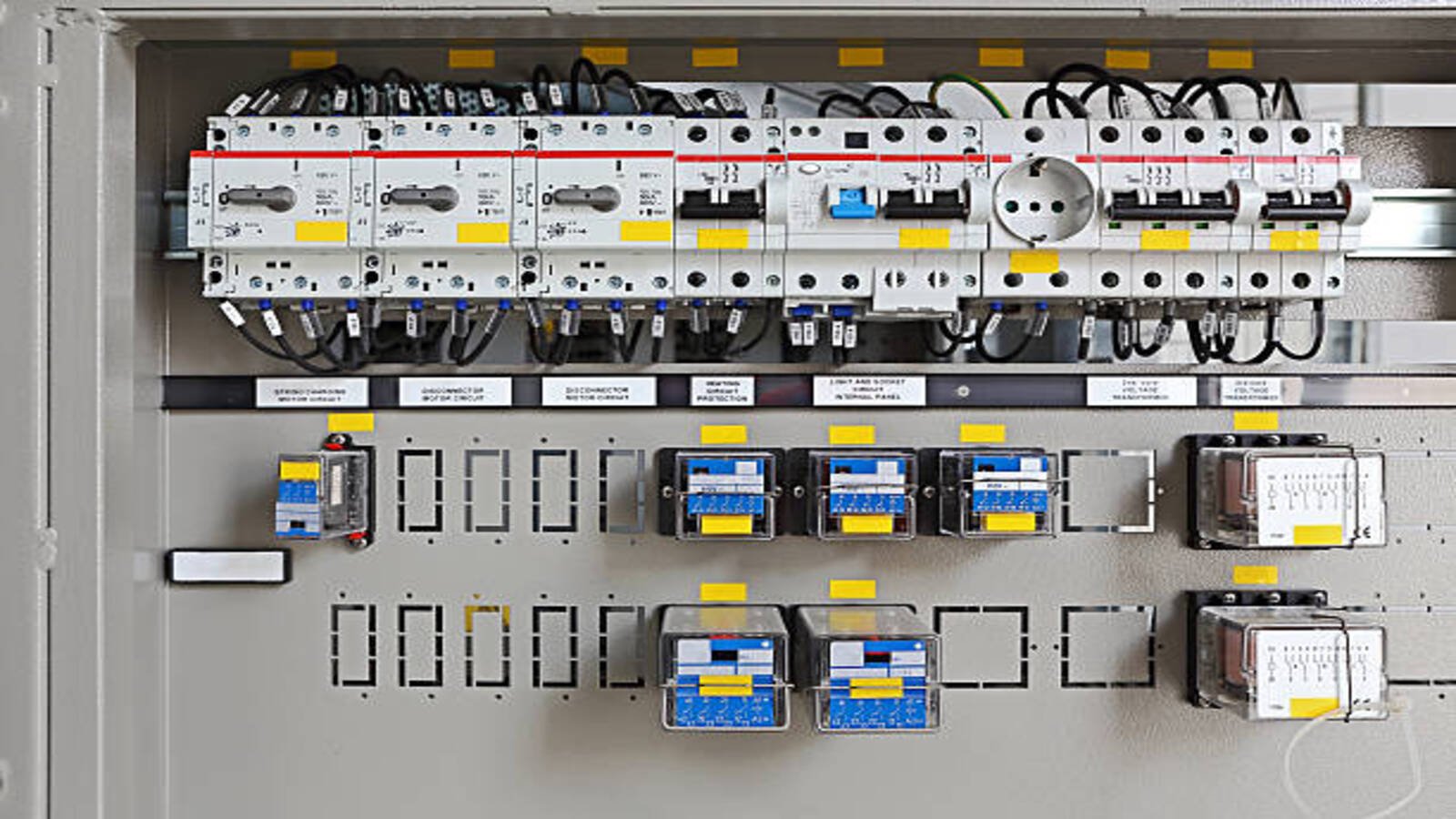

There are various mechanical parts involved in switchgear systems, including circuit breakers, disconnectors, contactors, relays, and busbars. Each of these components plays a crucial role in the operation of the system and requires precise processing to function effectively.

The Process of Processing Mechanical Parts

Switchgear mechanical parts processing involves several steps, including design, material selection, machining, assembly, and testing. Each step is critical to ensuring that the parts meet the required specifications and standards for safe and efficient operation.

Material Selection for Mechanical Parts

Choosing the right materials for switchgear mechanical parts is essential for their performance and longevity. Materials such as copper, aluminum, steel, and insulating materials are commonly used for different components to ensure proper conductivity and insulation.

Precision Machining for Mechanical Parts

Precision machining is crucial in the processing of switchgear mechanical parts to achieve accurate dimensions and smooth surfaces. CNC machining, milling, turning, and grinding are some of the techniques used to manufacture these components with high precision.

Assembly and Testing of Mechanical Parts

Once the individual parts are processed, they are assembled into the final switchgear system. This assembly process requires attention to detail to ensure that all components fit together correctly. Testing is then carried out to verify the functionality and safety of the system.

Quality Control in Mechanical Parts Processing

Quality control measures are essential throughout the processing of switchgear mechanical parts to ensure that they meet industry standards and specifications. Inspections, tests, and certifications are carried out at various stages of production to maintain quality and reliability.

Advancements in Mechanical Parts Processing

With technological advancements, the processing of switchgear mechanical parts has become more efficient and precise. Automation, robotics, and advanced software systems are now being used to streamline production processes and improve the quality of the components.

Challenges in Processing Mechanical Parts for Switchgear Systems

Despite advancements, there are still challenges in processing switchgear mechanical parts, such as cost control, lead times, and compliance with evolving industry standards. Manufacturers need to stay updated on the latest technologies and regulations to overcome these challenges.

Conclusion

In conclusion, switchgear mechanical parts processing is a critical aspect of low-voltage switchgear systems. By following proper procedures, using high-quality materials, and maintaining strict quality control, manufacturers can ensure the reliability and safety of these essential electrical systems.

Quote Inquiry

Contact us!