Precision metal processing techniques are critical for the successful production of high-quality metal products. These techniques involve the use of sophisticated machinery, tools, and methods to shape, cut, and form metal components with precision and accuracy. In this article, we will explore the different aspects of precision metal processing techniques.

Metal Cutting Techniques

Metal cutting techniques are an important part of precision metal processing. These techniques involve the use of various tools, such as saws and shears, to cut metal into specific shapes and sizes. Laser cutting is also a popular technique that uses a high-powered laser to cut through metal with precision and accuracy.

Metal Forming Techniques

Metal forming techniques involve the shaping of metal into specific forms, such as sheets, plates, and tubes. These techniques often involve the use of hydraulic presses, rollers, and other tools to bend, stretch, and shape metal into the desired form.

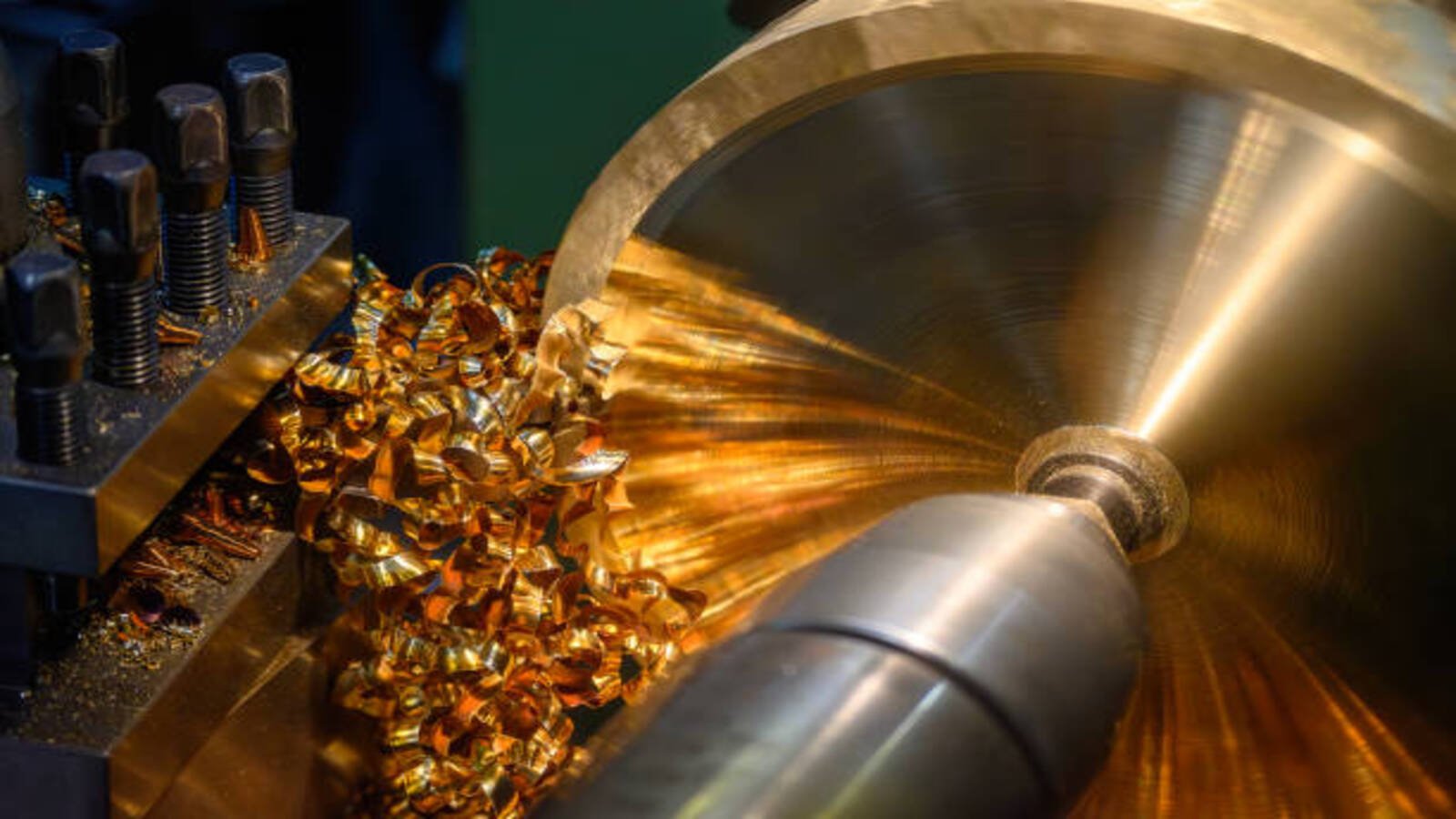

Machining Techniques

Machining techniques are another important aspect of precision metal processing. These techniques involve the use of computer-controlled machines, such as lathes and mills, to cut and shape metal components with high precision and accuracy.

Heat Treatment Techniques

Heat treatment techniques are used to alter the physical properties of metal components. These techniques involve heating metal to specific temperatures and cooling it rapidly to achieve desired characteristics, such as increased hardness or elasticity.

Surface Treatment Techniques

Surface treatment techniques are used to improve the quality and appearance of metal components. These techniques involve processes like polishing, grinding, and plating to create a smooth, shiny surface on the metal.

Quality Control Techniques

Quality control is an essential aspect of precision metal processing. Techniques like non-destructive testing, dimensional analysis, and visual inspection are used to ensure that metal components meet strict quality standards.

Applications of Precision Metal Processing Techniques

Precision metal processing techniques are used in a wide range of industries, including aerospace, automotive, electronics, and medical devices. These industries rely on precision metal components to ensure the safety, reliability, and performance of their products.

The Future of Precision Metal Processing Techniques

Advancements in technology are constantly improving precision metal processing techniques. The use of automation, robotics, and 3D printing is revolutionizing the way metal components are produced, making it faster, more efficient, and more precise than ever before.

Conclusion

Precision metal processing techniques are at the heart of modern metalworking. From cutting and forming to heat and surface treatments, these techniques play a vital role in the production of high-quality metal components. By embracing the latest advancements in technology, we can expect precision metal processing techniques to continue to evolve and improve, leading to even more efficient and effective metalworking processes.

Quote Inquiry

Contact us!