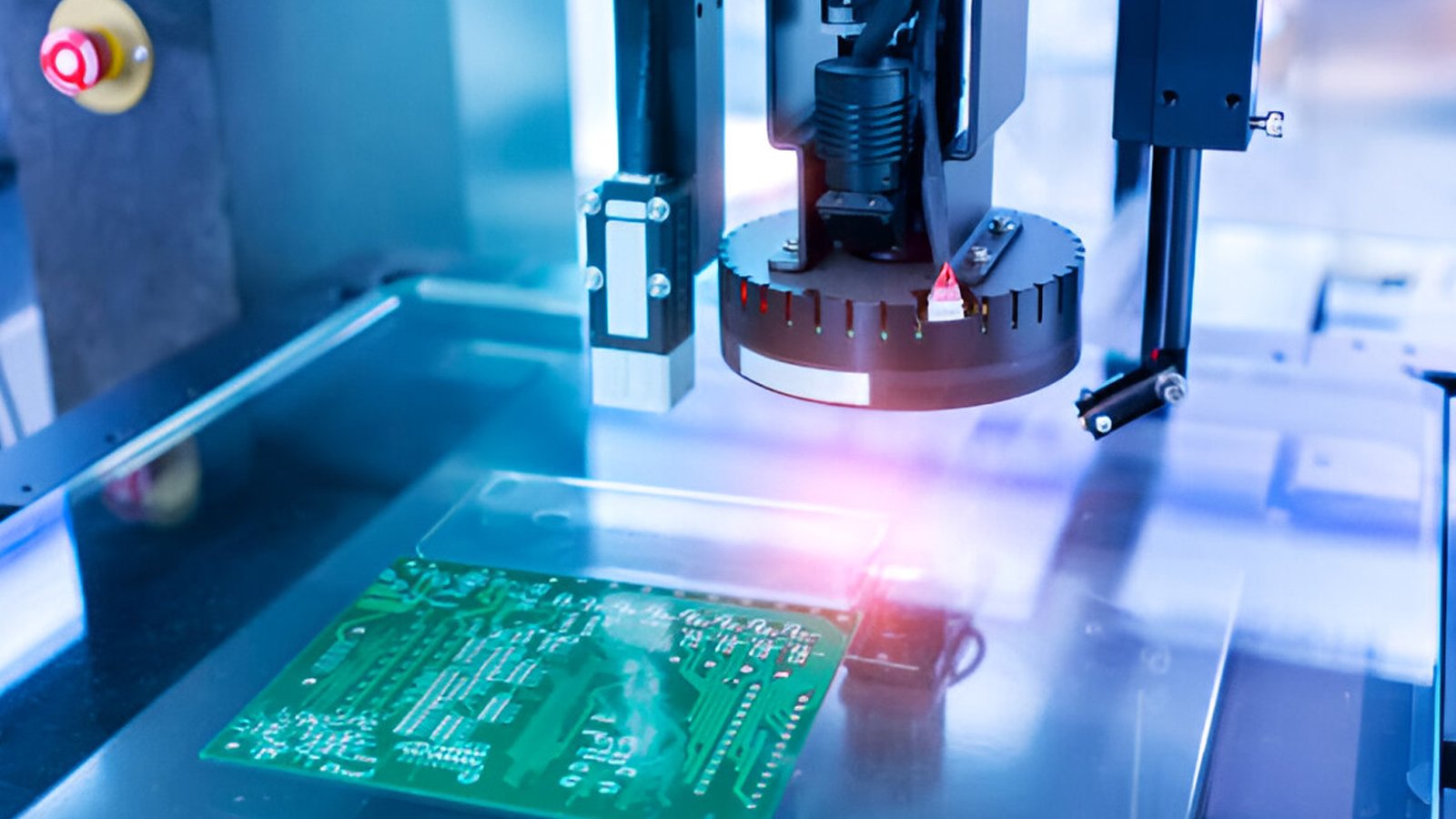

The Importance of Precision Machining in Creating High-Performance Parts

Precision machining is a critical process used in the manufacturing of high-performance parts. It is a process that involves the use of advanced technology and expertise to produce custom-designed components that meet the exact specifications required by various industries. Precision machining is important because it ensures that the parts produced meet the highest standards of quality and functionality.

The Different Techniques used in Precision Machining

There are different techniques used in precision machining, including turning, milling, drilling, and grinding. Turning involves the removal of excess material from the surface of a workpiece, while milling involves the use of a cutting tool to create complex shapes and designs. Drilling is used to create holes, while grinding is used to create high-quality finishes.

The Advantages of Precision Machining

Precision machining offers many benefits, including increased accuracy and precision in the parts produced. It can also lead to a reduction in scrap material and improved efficiency in the manufacturing process. Furthermore, precision machining can result in increased reliability and durability of the parts produced, which is essential in high-performance applications.

The Role of Computer Numerical Control (CNC) in Precision Machining

CNC machines are integral to precision machining, as they provide greater accuracy and precision in the manufacturing process. They are automated, computer-controlled machines that can carry out complex tasks with a high degree of accuracy. This makes them ideal for producing high-performance parts that require tight tolerances and exact specifications.

Materials Used in Precision Machining

The materials used in precision machining can vary depending on the specific application and requirements. Common materials used include metals such as aluminum, brass, stainless steel, and titanium. Plastics and composites may also be used, especially in applications where weight reduction is important.

The Importance of Quality Control in Precision Machining

Quality control is a vital aspect of precision machining, as it ensures that the parts produced meet the required specifications and standards. This involves using advanced inspection techniques and equipment to test the parts for accuracy and functionality. Quality control also involves monitoring the manufacturing process to ensure that it is performing at optimal levels.

The Future of Precision Machining

The future of precision machining is promising, as advancements in technology continue to improve the manufacturing process. The use of new materials and techniques, such as additive manufacturing, is also leading to new possibilities and applications for precision machining.

Applications of Precision Machining in Various Industries

Precision machining has applications in various industries, including aerospace, automotive, medical, and defense. In aerospace, precision machining is used to produce high-strength, lightweight components for aircraft. In the medical industry, precision machining is used to produce custom medical devices and implants with exact specifications.

Choosing the Right Precision Machining Service Provider

When choosing a precision machining service provider, it is important to consider factors such as experience, expertise, and equipment capabilities. The provider should have a track record of producing high-quality parts with tight tolerances and exact specifications. They should also have a commitment to quality control and testing to ensure that the parts produced meet the required standards.

The Cost of Precision Machining

Precision machining can be more expensive than other manufacturing methods, but the benefits of increased accuracy and reliability often outweigh the cost. The cost of precision machining can vary depending on the specific application and requirements, but it is important to work with a service provider who can provide a clear and transparent cost structure.

Quote Inquiry

Contact us