Metal machining services for automotive industries: Essential Information

The automotive industry is growing by leaps and bounds. In such an industry, it becomes essential to have timely and precise solutions that meet the manufacturing needs and standards for efficiency and productivity; this is where metal machining services come in.

What are Metal Machining Services?

Metal machining services refer to the process of shaping, cutting, and drilling metal components and parts that are used in industrial applications. These services are essential for automotive industries as they need precise and complex metal parts for their vehicles, and these parts need to be cost-effective and efficient.

Types of Metal Machining Processes

Metal machining services for the automotive industry employ several processes. Some of them are:

- Turning

- Drilling

- Milling

- Boring

- Broaching

Applications of Metal Machining in the Automotive Industry

Metal machining services are indispensable for the automotive industry. They help in producing different parts of the vehicle such as brake systems, engine components, gears, rotating shafts, transmission housings, and more.

The Benefits of Metal Machining Services for Automotive Industries

Metal machining services have several benefits for the automotive industry, including:

- Precision and accuracy in production

- Cost-effective production

- Efficiency in production time

- Flexibility in production quantity

- Quality Assurance

The Importance of Quality Assurance in Metal Machining Services

Quality assurance is critical in metal machining services. In the automotive industry, the parts produced have to meet the highest standards of quality and safety to ensure the best performance of the vehicle. Consequently, experienced and skilled metal machining professionals will always conduct a thorough inspection of all the produced parts to ensure they conform to specific quality standards.

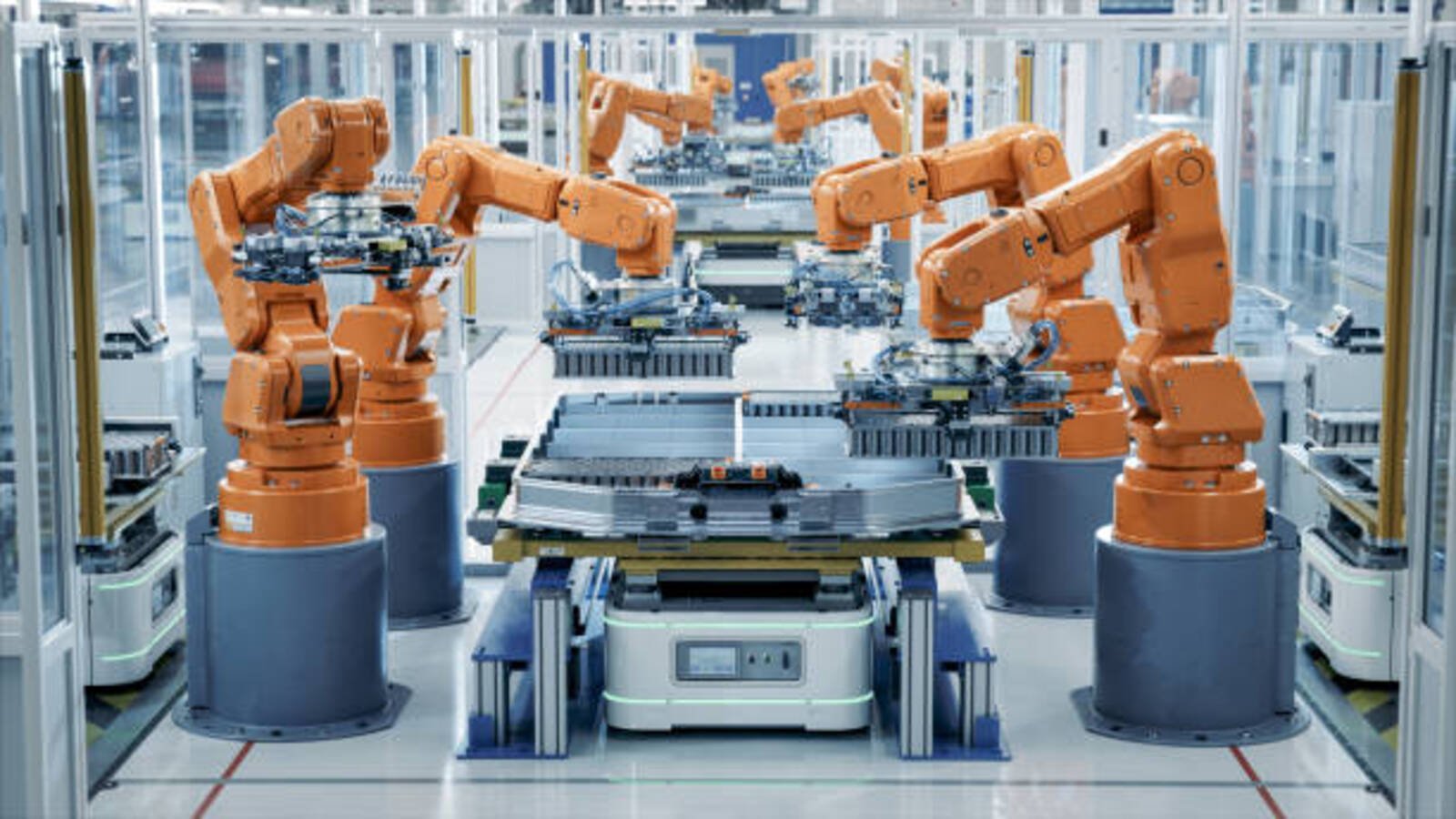

The Role of Technology in Metal Machining Services

Advancements in technology have played a massive role in metal machining services. They have led to the automation and precision in the manufacturing process, which leads to higher production rates and quality. The utilization of Computer Numerical Control (CNC) machining, laser cutting technology, and other high-tech machinery has made it easier and faster to manufacture complex parts and components with exceptional accuracy.

Factors to Consider When Choosing Metal Machining Services

When looking for metal machining services for your automotive parts production, you need to consider some essential factors such as:

- Experience of the company

- The type of metal machining processes available

- Their Quality Assurance processes

- Adaptation to technological advancements

- Flexibility in production quantity

- Affordable pricing for services

Choosing the Right Metal Machining Service Provider

It is challenging to find the right metal machining services provider for your automotive parts needs. Be sure to do some research into the company before settling on one. Read their reviews, look at their portfolio and compare pricing with other available options. Working with an experienced and reliable metal machining expert can significantly save you time and resources for your automotive production parts needs.

Conclusion

Metal machining services for the automotive industry are essential for producing high-quality, cost-effective, and efficient parts and components. Finding the right metal machining services provider is crucial to meeting the standards of the industry and achieving your goals for quality and safety levels.