Efficiency Improvements in Machining Techniques: Better, Faster, and More Accurate

Efficiency improvements in machining techniques are essential for achieving better, faster, and more accurate results in the manufacturing industry. Machining processes range from simple to complex, but they all have one thing in common: they are fundamental to the production of high-precision parts that meet the strict requirements of modern industry. In this article, we explore some of the most exciting developments in machining technology that are making the manufacturing process more efficient than ever before.

1. Liquid Cooling Systems

Overheating can be a major obstacle in the efficient machining of metals. To overcome this challenge, liquid cooling systems are utilized, which can significantly improve the efficiency of the machining process. In particular, the use of advanced cooling solutions, like high-pressure, high-velocity, and high-volume coolant systems, can drastically reduce the heat generated during machining.

2. Advanced Tool Materials

Efficiency improvements in machining are also being driven by advances in tool materials. High-performance tooling has increased the cutting speeds of machines, reducing the time required for machining and minimizing the need for manual intervention. The development of new carbide alloys and coated tool inserts has led to longer tool life and a reduction in the number of machine stoppages.

3. Automation and Robotics

The use of automation and robotics in machining has revolutionized the manufacturing industry. With automation, machines can operate continuously without the need for human intervention, resulting in faster and more efficient production. Robots are used in many machining operations to ensure precision, accuracy, and consistency, ensuring that every part produced is of high quality.

4. Precision Machining Tools

The development of precision machining tools has enabled manufacturers to produce high-precision parts that meet the most demanding specifications. Precision machining tools have the ability to produce parts with extremely tight tolerances, improving the overall quality of the final product. They also reduce the amount of material used and eliminate the need for secondary operations, reducing production time and costs.

5. High-Speed Machining (HSM)

High-speed machining, or HSM, is a process that utilizes high spindle speeds, feed rates, and depth of cut to remove material quickly. HSM is a highly efficient machining process that helps accelerate production rates and improve part quality. HSM can be used to machine almost any material, making it an ideal choice for manufacturing operations that require both speed and precision.

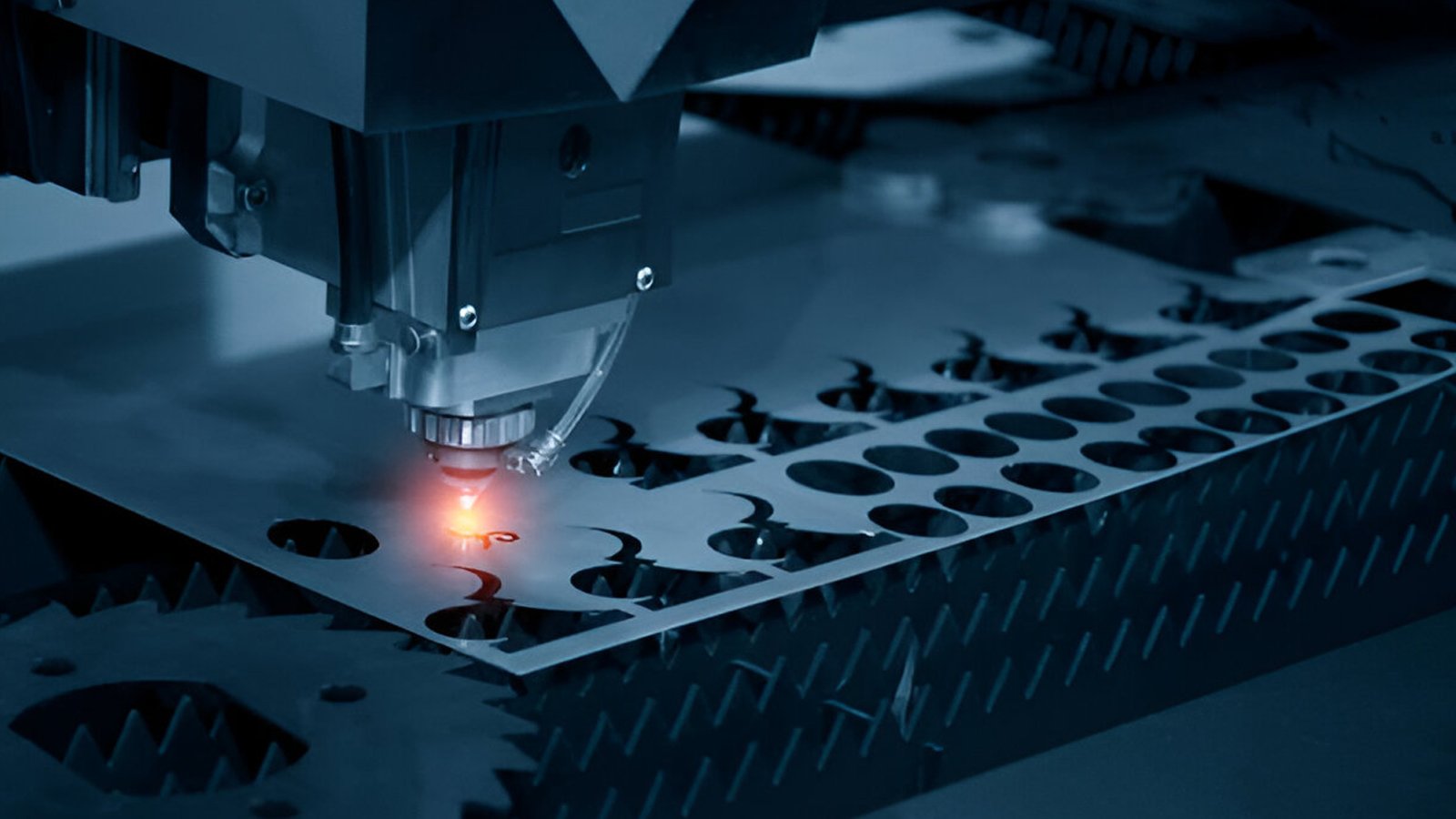

6. Computer Numerical Control (CNC) Machining

Computer numerical control, or CNC, machining is a process that utilizes computer-aided manufacturing (CAM) software to control cutting tools on a CNC machine. CNC machines are highly automated, with the ability to perform complex cutting operations with accuracy and speed. CNC machining has revolutionized the manufacturing industry, bringing efficiency improvements, precision, and versatility to manufacturing operations.

7. Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a process that uses digital models to build parts layer by layer. Additive manufacturing offers significant advantages over traditional machining techniques, with quicker setup times and the ability to produce complex shapes with fewer process steps. Additive manufacturing can also produce parts with less material waste and minimal material handling, which can reduce the overall costs of manufacturing.

8. Optimization Software

Optimization software is a tool that helps manufacturers identify and resolve inefficiencies in their manufacturing processes. Optimization software utilizes advanced algorithms to analyze data from manufacturing processes and provides actionable insights to improve efficiency. A significant advantage of optimization software is that it can quickly identify areas for improvement and provide guidance on the best solutions, resulting in significant time and cost savings.

9. Simulation Software

Simulation software is a tool that allows manufacturers to simulate their manufacturing processes, optimizing parts and manufacturing layouts before they are committed to production. Simulation software allows manufacturers to explore different scenarios and identify potential bottlenecks before investing in expensive equipment and facilities. This reduces the risk of production delays and improves overall process efficiency.

10. Lean Manufacturing

Lean manufacturing is a concept that emphasizes the elimination of waste from the manufacturing process. Lean manufacturing principles are designed to increase efficiency by streamlining the manufacturing process and eliminating any unnecessary steps or costs. By focusing on the elimination of waste, manufacturers can increase productivity, reduce costs, and improve product quality.