Introduction: Importance of Designing Aluminum Parts in Electronics

Designing electronic devices often require the use of aluminum parts due to its lightweight, durability, and corrosion resistance properties. However, designing these parts can be challenging and requires a certain level of expertise. This article provides 10

Design Tips for Aluminum Parts in Electronics to ensure a successful production process.

1. Consider Material Thickness

The thickness of the aluminum part should be considered during the design process. A thinner material can result in a more cost-effective and lightweight product, while thicker parts can provide additional strength and rigidity.

2. Keep Tolerances in Mind

Tolerances are an important factor to consider during the design process. This refers to the allowable variation in dimensions during the production process. It is essential to ensure that tolerances are kept in mind in order to produce a high-quality product that meets the required specifications.

3. Pay Attention to Surface Finish

The surface finish of the aluminum part can impact its functionality and longevity. Coatings and finishes can enhance resistance to corrosive elements and provide an aesthetically pleasing appearance. It is important to choose the appropriate coating and finish for the particular application.

4. Consider Extrusion Process

The extrusion process can provide significant benefits in terms of cost and production efficiency. By designing the aluminum part for extrusion, it is possible to reduce material waste and increase production speed.

5. Minimize Stress Concentration

Aluminum parts are prone to stress concentration, which can lead to material failure. To prevent this, it is important to design the part with smooth transitions and rounded edges, eliminating any sharp corners or sudden changes in dimension.

6. Choose the Right Alloy

There are numerous types of aluminum alloys available, each with their own unique properties. It is important to select the appropriate alloy for the desired application, taking into consideration factors such as strength, ductility, and corrosion resistance.

7. Utilize Computer-Aided Design Software

Computer-aided design (CAD) software can significantly aid in designing aluminum parts for electronics. This software can provide the ability to test and analyze designs, ensuring that the product meets all necessary requirements.

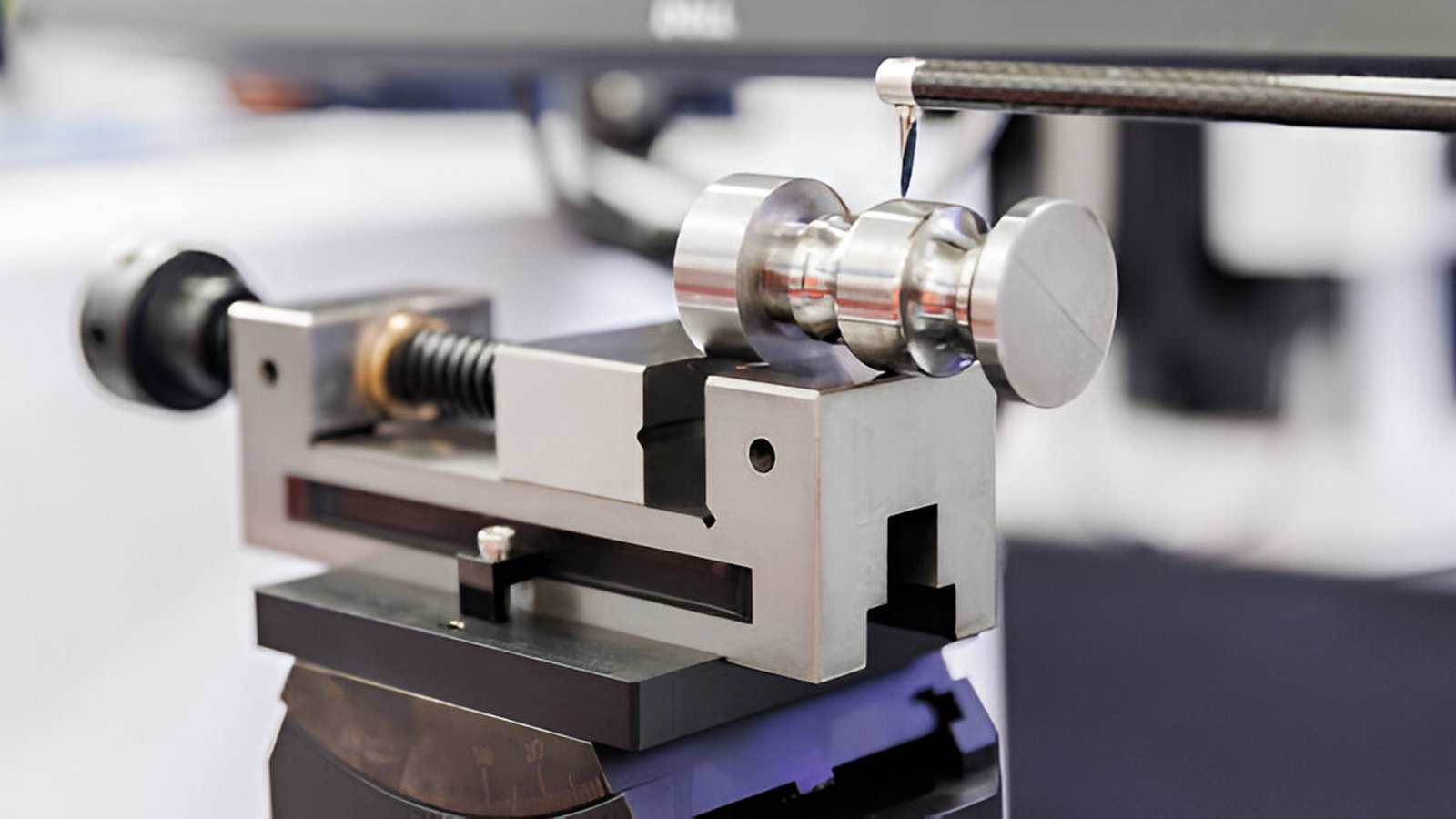

8. Properly Design for Machining

If the aluminum part requires machining, it is important to properly design the part to ensure accuracy and efficiency during the machining process. Properly designed features can significantly enhance the functionality and longevity of the product.

9. Consider Joining Techniques

Designing aluminum parts often requires the use of joining techniques such as welding, riveting, or adhesive bonding. It is important to consider the appropriate joining technique for the particular application, ensuring a strong and long-lasting bond.

10. Consider Environmental Factors

Aluminum parts used in electronics may be subjected to harsh environmental factors such as extreme temperatures, humidity, and corrosive elements. It is important to design the part with these factors in mind, utilizing appropriate coatings and finishes to increase resistance and durability.

aluminum parts in electronics, design tips, material thickness, tolerances, surface finish, extrusion process, stress concentration, appropriate alloy, computer-aided design software, proper machining, joining techniques, environmental factors

10 Design Tips for Aluminum Parts in Electronics

Designing aluminum parts in electronics can be challenging. This article provides 10 tips to ensure a successful production process, including material thickness, tolerances, surface finish, extrusion process, stress concentration, alloy selection, computer-aided design software, machining, joining techniques, and environmental factors.

Quote Inquiry

Contact us