Custom metal components for electrical systems are a vital part of any industrial operation. They are essential in the manufacturing of machinery or equipment that relies on electrical systems to function. In this article, we will discuss the benefits and uses of custom metal components for electrical systems.

Increased Durability

Custom metal components are usually made from high-quality materials that can withstand extreme conditions such as high temperatures and pressure. These components offer exceptional strength and durability, which is vital for equipment and machinery that are subjected to rigorous use.

Improved Flexibility

Custom metal components can be designed to fit specific requirements, making them highly adaptable to a wide range of electrical systems. They can be customized to meet unique specifications in the manufacturing process, such as the size, shape, and finish.

Better Heat Dissipation

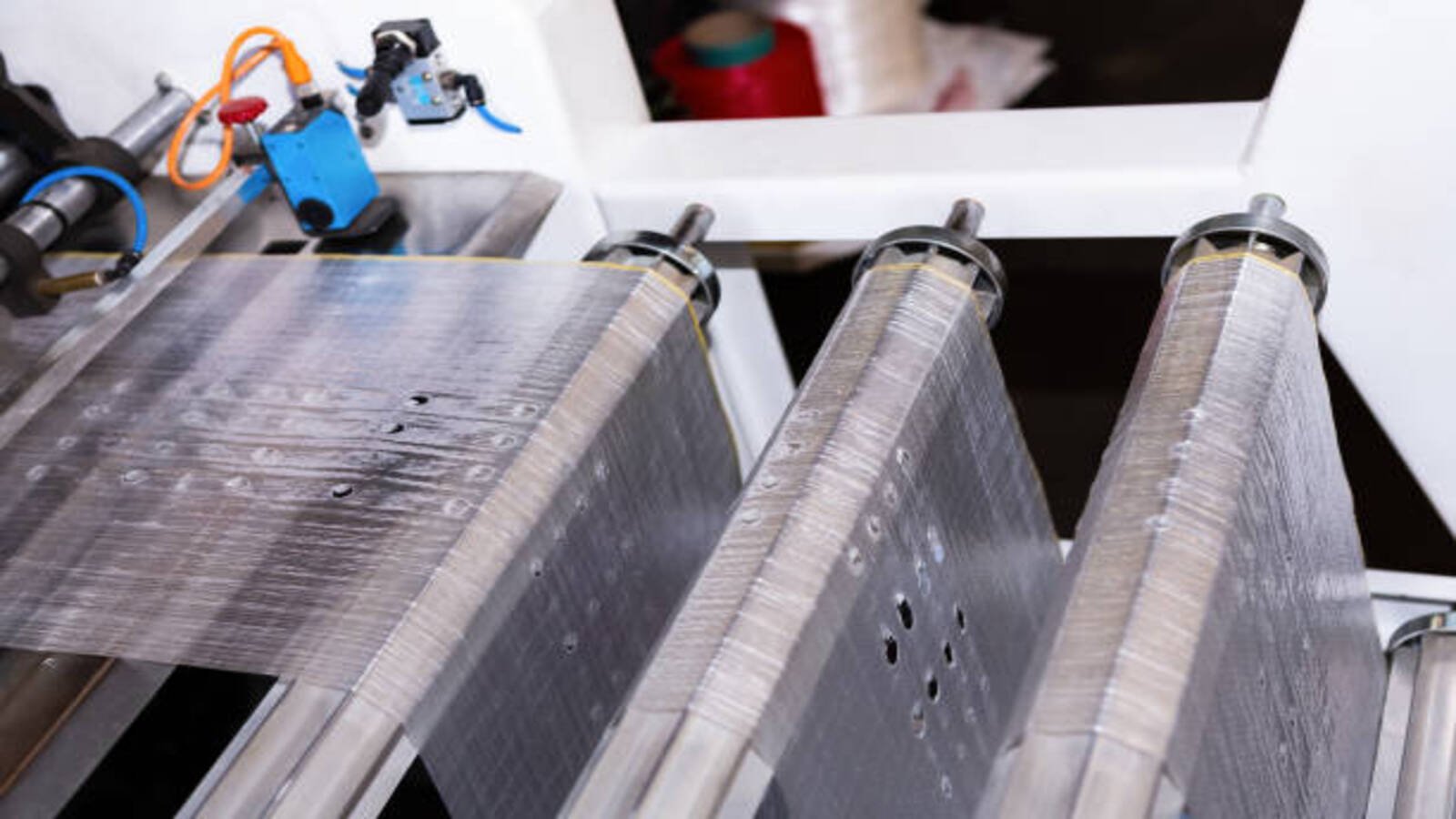

Electrical systems generate a significant amount of heat, which can be detrimental to their performance. Custom metal components, such as heat sinks, can be designed to remove heat from the system efficiently, ensuring optimal performance and reducing the risk of overheating.

Increased Efficiency

Custom metal components can help to improve the efficiency of electrical systems by minimizing power losses. By using custom components that have been designed to match specific requirements, electrical systems can achieve optimal performance, leading to increased output and reduced energy consumption.

Greater Precision

Custom metal components are designed using high-precision tools and technology. As a result, they offer a higher level of precision and accuracy than standard components. This translates to better performance and reliability, especially when used in sensitive industries such as aerospace and medical devices.

Enhanced Safety

Custom metal components can play a crucial role in enhancing safety in industrial environments. For example, in electrical systems used in hazardous locations such as chemical plants, custom components can be designed with safety features such as flame-resistant properties, enhancing equipment safety.

Cost-effective Solution

Although custom metal components may seem expensive compared to standard components, they offer long-term cost savings. This is because they are designed to meet specific requirements, reducing the risk of equipment damage and increasing the lifespan of machinery. Additionally, they reduce the need for frequent maintenance, leading to cost savings in the long run.

Quick Turnaround Times

Custom metal components can be rapidly designed and produced, thanks to the latest technologies such as 3D printing and CNC machining. This means that businesses can get the components they need within a short period, minimizing downtime and improving productivity.

Environmentally Friendly

Today's industries are becoming more environmentally conscious, and custom metal components can contribute to sustainability. For example, many components can be recycled at the end of their lifespan, reducing waste and contributing to a more sustainable future.

Conclusion

Custom metal components for electrical systems offer numerous benefits in terms of performance, durability, safety, and cost-effectiveness. Whether you are looking to improve the performance of your electrical systems or reduce maintenance costs, custom metal components could be the solution you have been looking for.