Comparing Machine Casting Methods for Efficiency: Which One is Right for You?

Machine casting has become an integral part of modern manufacturing, providing a reliable and accurate way to produce complex designs at a low cost. But with so many different casting methods available, it can be hard to know which one is right for your project. In this article, we take a closer look at some of the most popular casting methods and compare them for efficiency.

1. Sand Casting

Sand casting is one of the oldest casting methods but still widely used today. The process involves using a molded sand mold to cast metal components. This method is suitable for producing large and complex components. However, it is time-consuming, labor-intensive, and may not be suitable for high-volume production runs.

2. Investment Casting

Investment casting, also known as lost-wax casting, is a precision casting method that is suitable for producing complex components with intricate details. This method involves creating a wax pattern, which is then coated in a ceramic shell and burned out to create the final metal part. Investment casting provides great dimensional accuracy, surface finish, and intricate details. However, this method is more costly than other casting methods and is not suitable for large volume production runs.

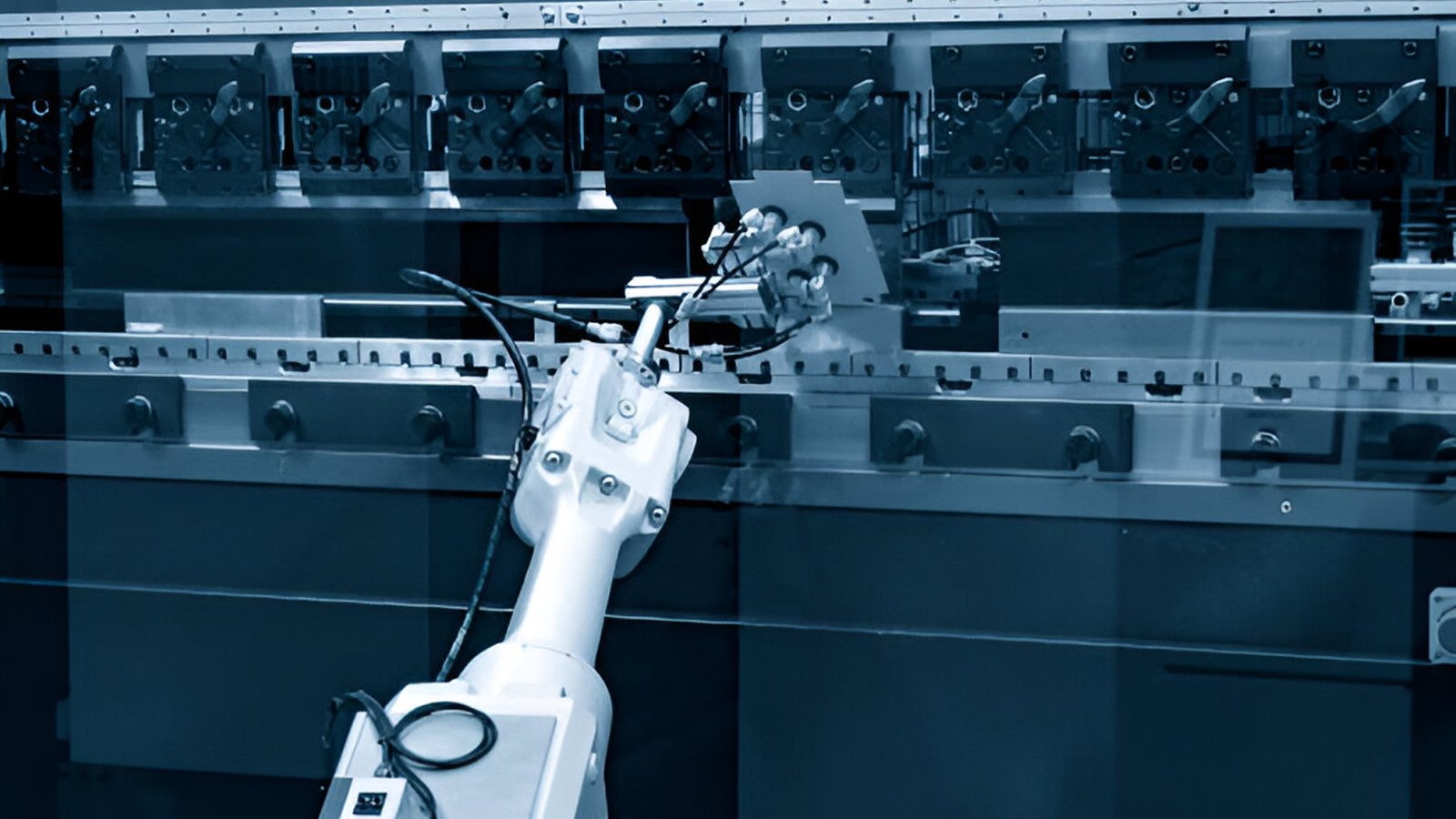

3. Die Casting

Die casting is the process of injecting molten metal into a steel mold, under high pressure, to produce complex shapes. Die casting is suitable for high volume production runs and is an economical way to produce precision metal parts. However, die-casting is limited by the size and complexity of the part that can be produced. It is also less suitable for producing parts with deep or thick sections, as a result of the solidification rate.

4. Permanent Mold Casting

The permanent mold casting method, also known as gravity die casting, is similar to die casting but uses a reusable metal mold to produce metal parts. This method is suitable for producing parts with complex shapes, high dimensional accuracy, and fine surface finish. Permanent mold casting provides faster production speeds, better tolerances, and more consistent parts. However, the cost of creating a mold for permanent mold casting is higher than that of sand casting, and the mold will wear out over time.

5. Centrifugal Casting

Centrifugal casting is a casting process in which the metal is poured into a spinning mold to produce cylindrical or symmetrical parts. This process is suitable for producing long and thin components, such as pipes, tubes, and wheels. This method provides high production rates and excellent metallurgical properties, ensuring that the cast part is free of porosity and inclusions. However, this method is not suitable for complex shapes, and the equipment cost can be high.

6. Low Pressure Die Casting

Low-pressure die casting is a casting method that uses a furnace to melt metal and a press to pump the metal into a mold. This method is similar to die-casting but uses lower pressure. Low-pressure die casting is suitable for producing medium to large, simple to complex components. This method is preferable for cast components whose tensile strength is greater than the ones casted with high-pressure die casting. This casting method has its advantages in achieving excellent surface finish and low porosity.

7. High-Pressure Die Casting

High-pressure die casting is a casting method that uses a high-pressure injection system to force molten metal into a mold. This method is suitable for producing high-volume components such as brass parts and aluminum alloy parts. High-pressure die casting provides excellent dimensional accuracy and surface finish, making it ideal for producing intricate designs. However, this method is limited by the size of the part that can be produced, as well as the cost of the tooling and equipment.

8. Vacuum Casting

Vacuum casting is a casting method that uses the principle of vacuum to remove the air from the mold and create a vacuum seal. This method is suitable for producing small to medium-sized components in low-to-medium production volumes. Vacuum casting provides excellent surface finish, dimensional accuracy, and reproducibility. Moreover, this method can be used with a variety of materials, such as thermoplastics and silicone rubbers. However, this method is limited by the size of the part that can be produced and is not as cost-effective compared to other casting methods.

9. Continuous Casting

Continuous casting is a casting method that involves casting molten metal into a mold that moves continuously. This method is suitable for producing long and uniform components, such as wires and profiles. Continuous casting provides high production rates and cost-effectiveness, ensuring that the cast part is free of porosity and inclusions. However, this method is not suitable for high precision parts or components with intricate designs.

10. Conclusion

Choosing the right casting method is essential to ensure you achieve the final product's desired quality, accuracy, and price. Each casting method has its advantages and disadvantages, making it important to assess which method best suits your product.