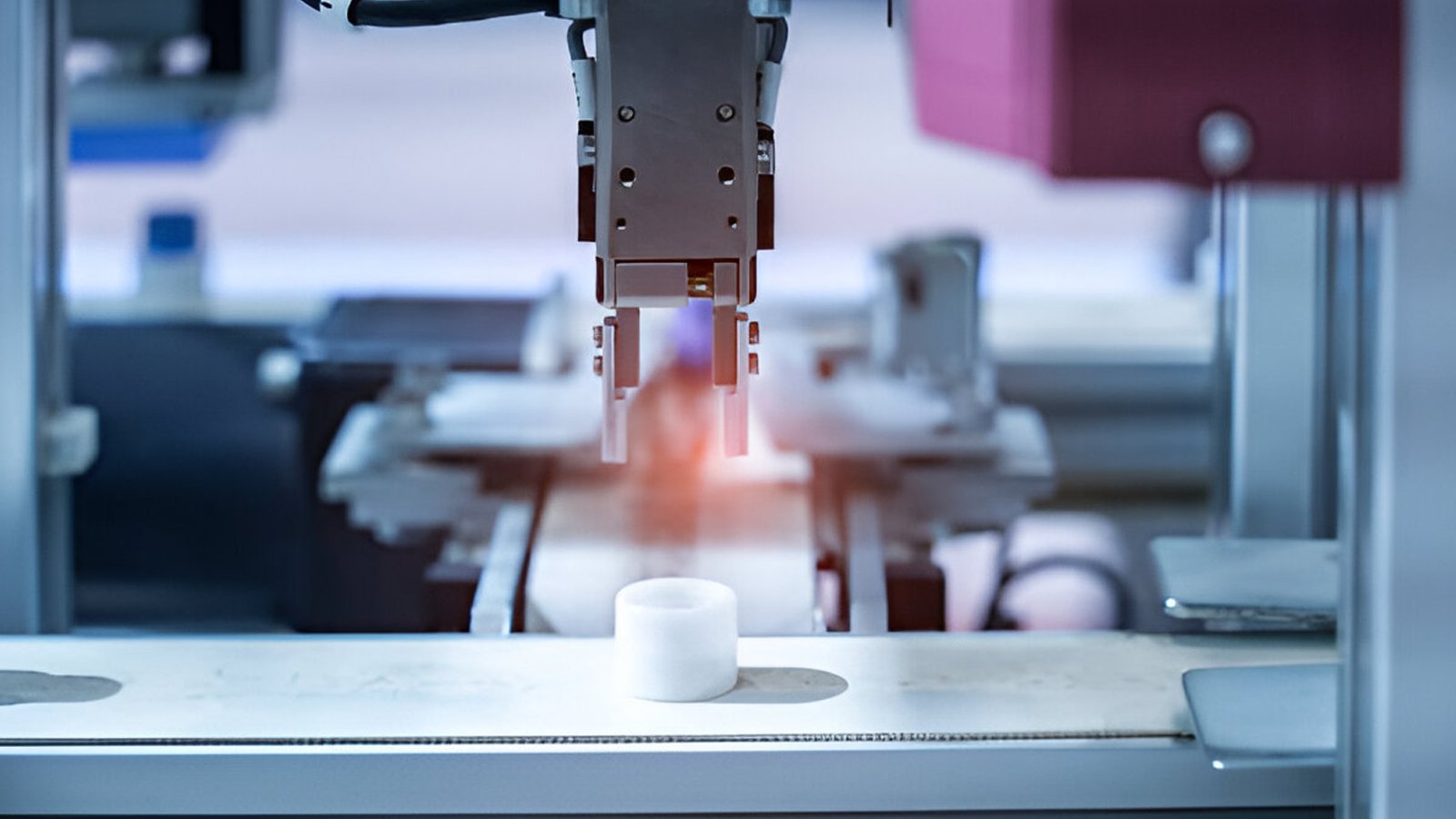

Advanced machining methods for complex parts refer to the processes and techniques used to manufacture intricate and multi-faceted components. These methods are designed to enable engineers to make parts that are more accurate, reliable, and cost-effective than ever before. This article will delve into the various aspects of these machining methods, including their benefits, innovations, and applications.

The Importance of Advanced Machining Methods for Complex Parts

The need for advanced machining methods for complex parts has arisen due to the increasing demands of technology and industry. In today's world, everything from cars to medical devices requires complex components that are efficient, durable, and cost-effective. These advanced machining methods enable engineers to design and produce parts that are more complicated than ever before, ensuring that they meet quality and safety standards while improving efficiency and reducing production time.

The Latest Innovations in Advanced Machining Methods

One of the most exciting innovations in advanced machining methods for complex parts is the use of high-speed machining. This technology enables engineers to produce more intricate parts in less time and with fewer errors. Another innovation is the use of multi-axis machining, which allows engineers to create complex components with a higher level of precision than ever before. These innovations are helping to make advanced machining methods more accessible and effective for a wide range of industries.

The Benefits of Advanced Machining Methods for Complex Parts

There are numerous benefits to using advanced machining methods for complex parts. These methods enable engineers to create parts that are more accurate, reliable, and cost-effective. They also enable them to produce parts that are more durable and efficient, which can translate into significant savings for end-users. Furthermore, advanced machining methods can help to reduce overall manufacturing costs, as they require fewer materials, less energy, and less time to produce.

Applications of Advanced Machining Methods for Complex Parts

Advanced machining methods for complex parts have numerous applications across a broad range of industries. They are used to manufacture everything from automotive parts to medical devices to aerospace components. These methods are particularly beneficial for producing parts that require intricate designs, high levels of precision, and strict quality control. With the rise of additive manufacturing and 3D printing technology, the possibilities for advanced machining methods are only continuing to grow.

The Role of CAD/CAM Software in Advanced Machining Methods

One of the key drivers of advanced machining methods for complex parts is the use of computer-aided design and computer-aided manufacturing (CAD/CAM) software. This software enables engineers to design complex parts with a higher level of precision and accuracy. It also helps to automate the manufacturing process, reducing the risk of errors and improving efficiency. CAD/CAM software has become an essential tool for engineers working in industries that require complex components.

The Future of Advanced Machining Methods for Complex Parts

The future of advanced machining methods for complex parts looks bright. With ongoing innovations in high-speed machining, multi-axis machining, and CAD/CAM software, engineers will be better equipped than ever to design and produce parts that are more intricate, precise, and efficient. As the demand for complex components continues to grow across various industries, advanced machining methods will likely become increasingly essential.

Challenges and Limitations of Advanced Machining Methods for Complex Parts

While there are numerous benefits to using advanced machining methods for complex parts, there are also some challenges and limitations. One of the biggest challenges is the cost of equipment and materials, which can be significant. Additionally, the process of designing and producing complex components can be time-consuming and require a high level of expertise. However, with ongoing advancements in technology and automation, these challenges may become less significant in the future.

The Importance of Choosing the Right Machining Methods

Choosing the right machining methods for the production of complex parts is crucial. The decision will depend on various factors, including the intended application of the part, the desired level of precision, and the available budget. Some machining methods are better suited for high-volume production, while others are more useful for creating custom or one-off components. Understanding the various pros and cons of different machining methods is crucial for making informed decisions about which method to choose.

The Bottom Line

Advanced machining methods for complex parts are vital for modern industries. These methods enable engineers to design and produce parts that are more intricate, precise, and efficient than ever before. As technology continues to advance, the possibilities for advanced machining methods are only continuing to expand. Companies that invest in these methods will be better equipped to compete in a rapidly evolving global marketplace.