Revolutionizing the Welding Process with Collaborative Robots

Automated welding processes are not new. However, the introduction of collaborative robots or cobots has completely revolutionized the industry with their ability to take over repetitive welding jobs and freeing up humans to tackle complex tasks such as programming. Cobots offer better accuracy, speed, and cost savings in the welding process.

3D Metal Printing is Changing the Game

3D metal printing is gaining popularity in the manufacturing industry. This technology can help companies bring their Metal Processing projects to life, save time, and cost. From aerospace giants to small-scale jewelry makers, 3D printing has opened up endless possibilities.

Trends in automated metal processing has opened a new era of customized solutions and creativity.

The Rise of IoT in the Metal Industry

The adoption of IoT In the metal industry has been gaining momentum with the help of Automated Metal Processing. The IoT–driven systems provide automation and optimize manufacturing processes, reduce downtime, and improve overall product quality. IoT’s data-driven decision-making tools are helping the metal industry increase efficiency and reduce costs.

The Speed and Reliability of Automated Laser Cutting Technology

Automated Laser Cutting is an efficient way to cut and fabricate metal. Advancements made in material handling and software programming technology have made this process faster and more reliable. Automated Laser Cutting Machines have streamlined the manufacturing process, improve precision, reduce errors and also generally safer for those operating the machine.

Automated Metal Stamping Solutions

Metal stamping requires precision and repeatability. Automation provides manufacturers with this and other important advantages. Automated metal stamping solutions help companies enhance productivity, reduce waste, improve accuracy, and reduce downtime.

Automated Heat Treatment of Metals

Selecting the right heat treatment schedule plays a crucial update in the metallurgical properties of metals. Automated heat treatment systems have revolutionized Metallurgical processes by providing advanced control and precise temperature regulation. This technology helps manufacturers achieve consistency in quality, increase productivity, and decrease the likelihood of human error.

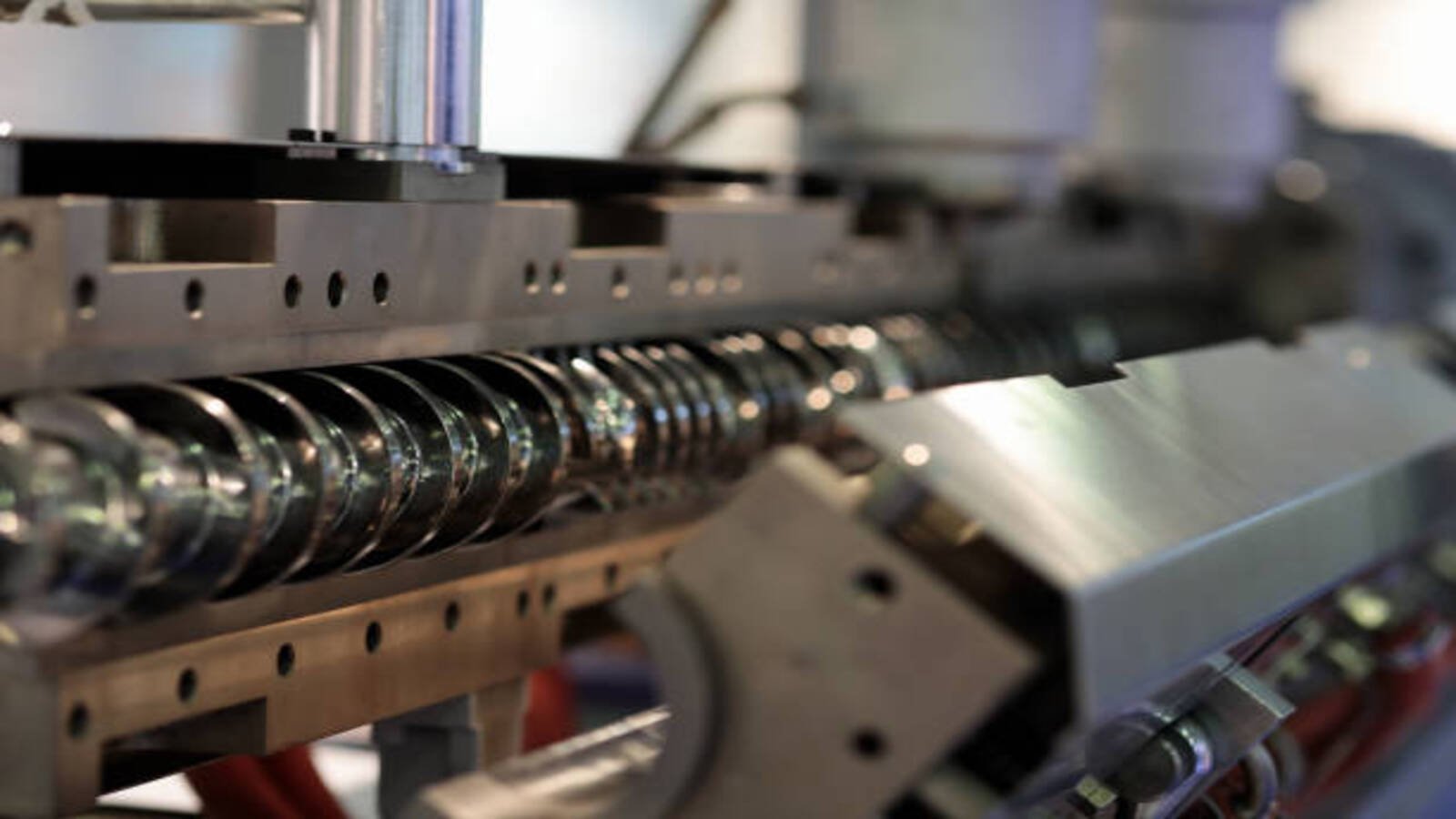

Automated Grinding and Finishing

Manual grinding and finishing are tedious, time-consuming, and prone to error. Automated grinding and finishing provides accuracy and speed, enabling manufacturers to improve the surface finish of their products while reducing production time.

Cutting Down on Wastage with Automated Material Processing

The manufacturing process can generate significant waste, which can impact both the environment and the companies' bottom line. Automated material processing helps companies reduce waste, optimize material usage, and help sustainability efforts with manufacturing.

The Flexibility of Automated Bending and Forming Solutions

Automated bending and forming solutions are efficient in fabrication. Robotic systems can handle a wide range of metal forming operations which is effective in the aerospace, automotive, and manufacturing industries. Automated bending and forming offer flexibility in production and also eliminates human error.

Streamlining Polishing Processes with Automation

Automated polishing systems play a vital role in producing high-quality metal parts. These systems provide automation and performance benefits, such as improving surface conditions of Metal parts and Improve overall production efficiency. Automated polishing is ideal for producing metal parts that require a high level of surface finishing and consistency.

Quote Inquiry

Contact us!