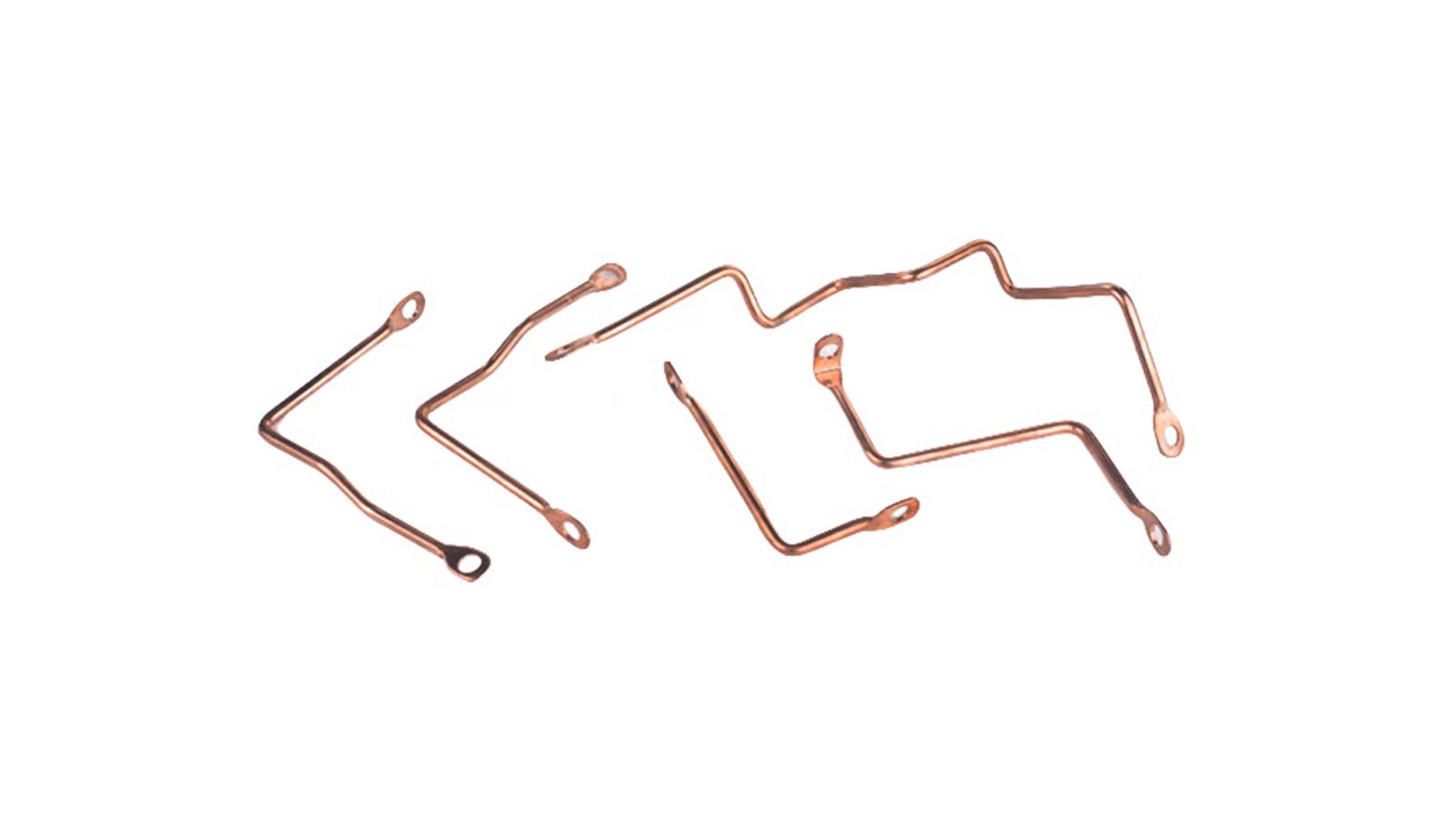

Understanding Contact Arms in Electrical Components

Contact arms are critical components in electrical systems that facilitate the transfer of current between different parts of a circuit. These components must be machined with precision to ensure optimal performance and reliability.

The Role of Quality Control in Machining

Quality control in machining contact arms involves closely monitoring the manufacturing process to ensure that each component meets the required specifications. This helps to prevent defects and inconsistencies that could lead to malfunction or failure in the electrical system.

Precision Machining Techniques

To achieve the necessary level of precision in machining contact arms, specialized techniques such as CNC machining are often employed. These techniques allow for extremely accurate cuts and measurements, ensuring that each component is identical and up to standard.

Testing and Inspection Processes

After the machining process is complete, contact arms undergo rigorous testing and inspection procedures to verify their quality. This may include dimensional checks, electrical conductivity tests, and visual inspections to identify any defects or imperfections.

Ensuring Durability and Longevity

Quality control measures in machining electrical components like contact arms help to guarantee their durability and longevity in the field. Components that are manufactured with precision and attention to detail are less likely to fail prematurely, saving time and money on replacements.

Compliance with Industry Standards

Manufacturers of electrical components must adhere to strict industry standards and regulations to ensure the safety and reliability of their products. Quality control in machining contact arms helps to meet these requirements and maintain high levels of customer satisfaction.

Continuous Improvement and Innovation

By implementing quality control measures in the machining process, manufacturers can identify areas for improvement and innovation. This ongoing process of refinement helps to enhance the performance and quality of contact arms over time.

Reducing Costs and Waste

Quality control in machining electrical components can also lead to cost savings and waste reduction. By catching defects early in the manufacturing process, manufacturers can avoid costly rework and scrap, ultimately improving their bottom line.

Supplier Collaboration and Communication

Effective quality control in machining contact arms often involves collaboration and communication with suppliers. By maintaining open lines of communication and setting clear expectations, manufacturers can ensure that their components meet the required quality standards.

Conclusion

In conclusion, quality control is a crucial aspect of machining electrical components like contact arms. By focusing on precision, testing, compliance, and continuous improvement, manufacturers can produce high-quality components that are reliable, durable, and safe for use in various electrical systems.