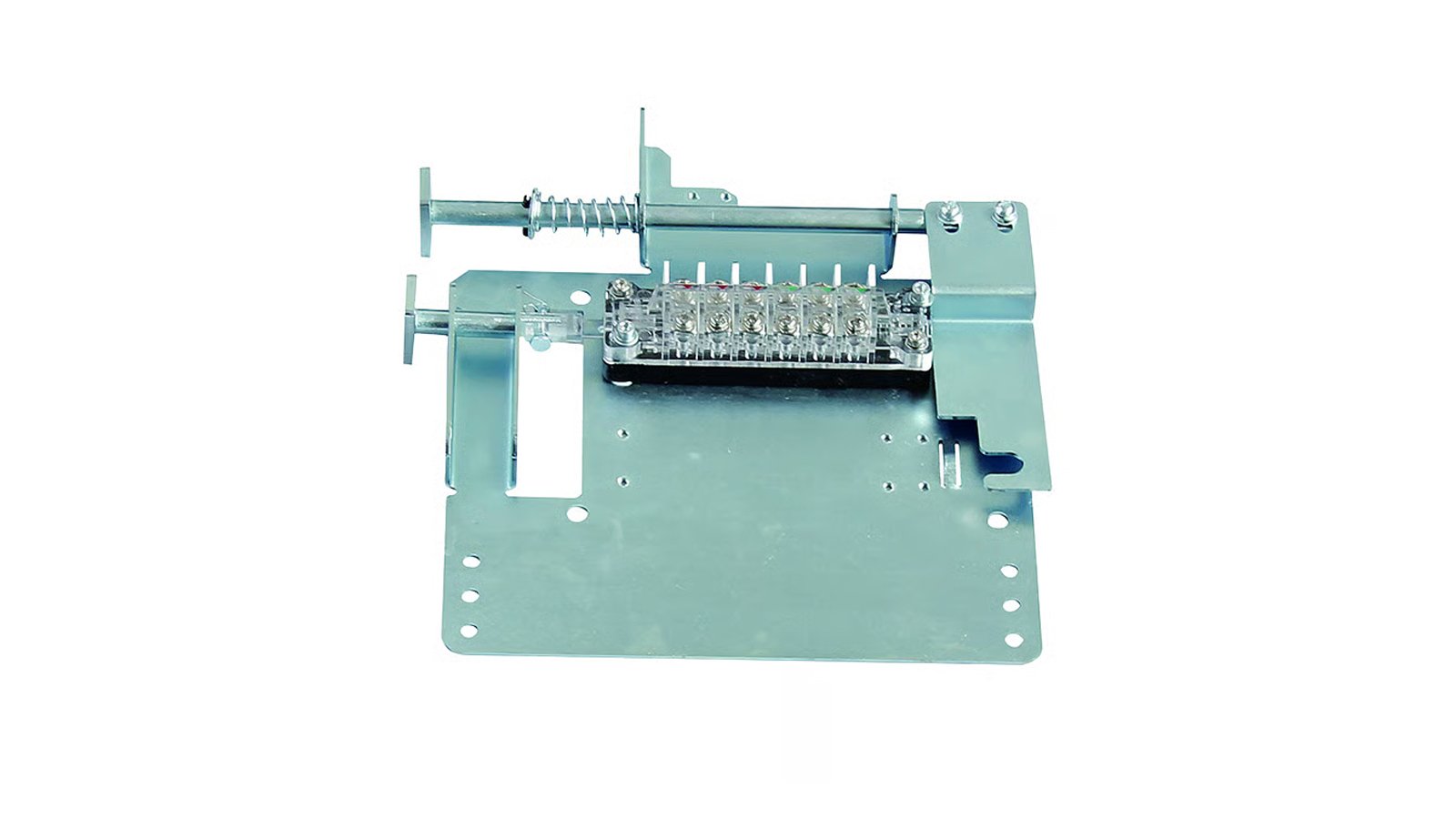

CNC machining is a precision manufacturing process that is ideal for producing high voltage components with intricate designs. This process uses computer-controlled machinery to execute complex cuts and shapes with a high level of accuracy, ensuring consistency and quality in the final product.

High Voltage Applications

High voltage components play a crucial role in various industries, including aerospace, automotive, and electronics. These components need to withstand high levels of electrical current and voltage, making precision machining essential to ensure their reliability and performance in demanding applications.

Material Selection

When manufacturing high voltage components, the choice of materials is critical to their performance and longevity. CNC machining allows for the use of a wide range of materials, including aluminum, copper, and plastics, to meet the specific requirements of high voltage applications.

Tolerances and Specifications

High voltage components must meet strict tolerances and specifications to ensure their proper functioning and safety. CNC machining provides the ability to achieve tight tolerances and precise specifications, resulting in components that perform as intended and meet industry standards.

Customization and Complexity

CNC machining offers the flexibility to customize high voltage components according to the unique requirements of each application. Whether it's complex geometries, intricate designs, or specific features, CNC machining can deliver highly customized components that fulfill the needs of the project.

Efficiency and Cost-effectiveness

By automating the manufacturing process, CNC machining increases efficiency and reduces production time, leading to cost savings for high voltage component manufacturers. This technology also minimizes material waste and ensures consistent quality across batches, making it a cost-effective solution for producing high precision components.

Quality Control

Quality control is paramount when producing high voltage components, as any defects or imperfections can compromise the safety and reliability of the final product. CNC machining enables rigorous quality control measures through its precise cutting and shaping capabilities, ensuring that each component meets the highest standards of quality.

Prototyping and Testing

CNC machining is ideal for prototyping high voltage components before full-scale production, allowing designers to iterate and test different designs quickly and cost-effectively. This iterative process helps identify and address any issues early on, leading to improved final products that meet all performance requirements.

Environmental Considerations

In addition to its precision and efficiency, CNC machining is also a sustainable manufacturing technology that minimizes environmental impact. By optimizing material usage and reducing energy consumption,

CNC machining for high voltage components supports environmentally friendly practices in the manufacturing industry.

Future Trends and Innovations

As technology continues to advance, CNC machining for high voltage components will evolve to incorporate new materials, processes, and designs. From advanced software systems to innovative tooling technologies, the future of CNC machining holds exciting possibilities for enhancing the production of high voltage components in various industries.

Quote Inquiry

contact us