The Importance of Machine Casting Components in Engineering Excellence

Engineering excellence is the cornerstone of progress and innovation in various industries. To achieve this excellence, engineers rely on a range of advanced technologies and components. One such crucial component is machine casting. Machine casting components play a pivotal role in enabling innovation in motion across different sectors, from automotive to aerospace. In this article, we will explore the significance of machine casting components in engineering excellence and how they contribute to driving innovation forward.

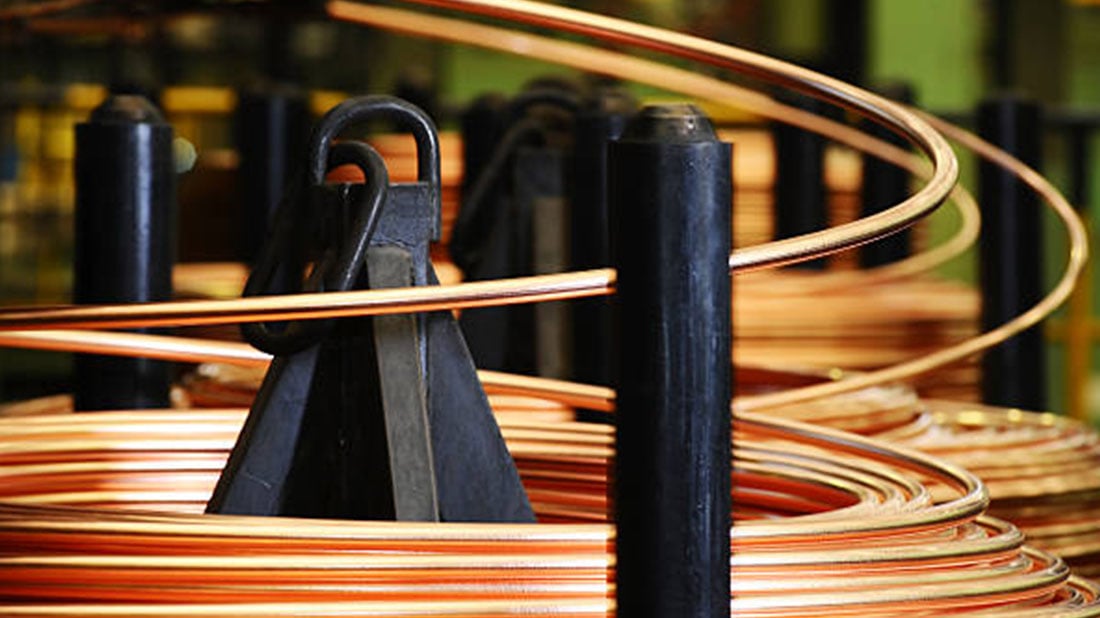

1. Understanding Machine Casting Components

Machine casting components refer to the parts and elements that are produced through the process of casting. Casting involves pouring molten metal into a mold and allowing it to solidify, resulting in a specific shape and size. These components are widely used in engineering applications due to their excellent strength, durability, and ability to be formed into complex shapes with precision.

2. Enhancing Design Flexibility

One of the key advantages of machine casting components is their ability to offer enhanced design flexibility. Traditional manufacturing methods often impose limitations on the shapes and structures that can be produced. However, with machine casting, engineers have the freedom to design intricate and complex components that meet their specific requirements. This flexibility enables the creation of innovative solutions that push the boundaries of engineering excellence.

3. Achieving Optimal Performance

Machine casting components are favored in engineering applications because they can be tailored to deliver optimal performance. By carefully selecting the material composition and adjusting the casting process parameters, engineers can achieve the desired mechanical properties, such as strength, hardness, and wear resistance. This customization allows for the creation of components that can withstand extreme conditions and perform flawlessly in critical applications.

4. Cost-Effectiveness in Manufacturing

Another aspect that makes machine casting components essential in engineering excellence is their cost-effectiveness in manufacturing. Casting processes, such as sand casting or investment casting, enable the production of large quantities of components with minimal material waste. This efficiency translates into reduced production costs, making machine casting an economically viable choice for industries aiming to achieve engineering excellence without compromising on quality.

5. Enabling Lightweight and Fuel-Efficient Designs

In the pursuit of engineering excellence, weight reduction and fuel efficiency are crucial factors, particularly in the automotive and aerospace industries. Machine casting components contribute significantly to these goals by offering lightweight alternatives to traditionally heavier components. By utilizing materials with high strength-to-weight ratios, such as aluminum or titanium alloys, engineers can design vehicles and aircraft that are not only more fuel-efficient but also provide superior performance and safety.

6. Ensuring Precision and Dimensional Accuracy

Machine casting components are renowned for their ability to deliver exceptional precision and dimensional accuracy. The casting process allows for the creation of intricate geometries with tight tolerances, ensuring that each component fits perfectly into the overall assembly. This precision is vital in engineering applications where even the slightest deviation can lead to performance issues or safety concerns. By relying on machine casting, engineers can achieve the required precision and maintain the highest standards of engineering excellence.

7. Facilitating Rapid Prototyping and Iterative Design

Machine casting components play a crucial role in facilitating rapid prototyping and iterative design processes. The ability to quickly produce functional components through casting allows engineers to test and validate their designs before committing to full-scale production. This iterative approach enables them to identify and resolve any issues or improvements early on, leading to more refined and innovative solutions. Machine casting thus acts as a catalyst for engineering excellence by promoting a culture of continuous improvement and innovation.

8. Supporting Complex Integration and Assembly

Integration and assembly of various components are fundamental in engineering excellence. Machine casting components excel in this regard due to their compatibility with other manufacturing processes. Whether it is machining, welding, or fastening, machine casting components can be seamlessly integrated into the overall assembly. This compatibility simplifies the production process, reduces the chances of errors or inconsistencies, and ensures a smooth and efficient workflow, all contributing to achieving engineering excellence.

9. Enhancing Durability and Longevity

In demanding engineering applications, durability and longevity are paramount. Machine casting components offer exceptional resistance to wear, corrosion, and fatigue, making them ideal for industries that require components to withstand harsh environments or repetitive loading. By incorporating machine casting components into their designs, engineers can ensure the longevity and reliability of their products, which are essential attributes of engineering excellence.

10. Driving Innovation Forward

Machine casting components are not just instrumental in achieving engineering excellence today; they also drive innovation forward for tomorrow. The continuous research and development in casting technologies, materials, and processes allow engineers to explore new possibilities and push the boundaries of what is achievable. By embracing the role of machine casting components, industries can foster a culture of innovation, enabling them to stay at the forefront of technological advancements and maintain their commitment to engineering excellence.