Ensuring Reliability: Testing Procedures for Switchgear Mechanical Systems

Introduction

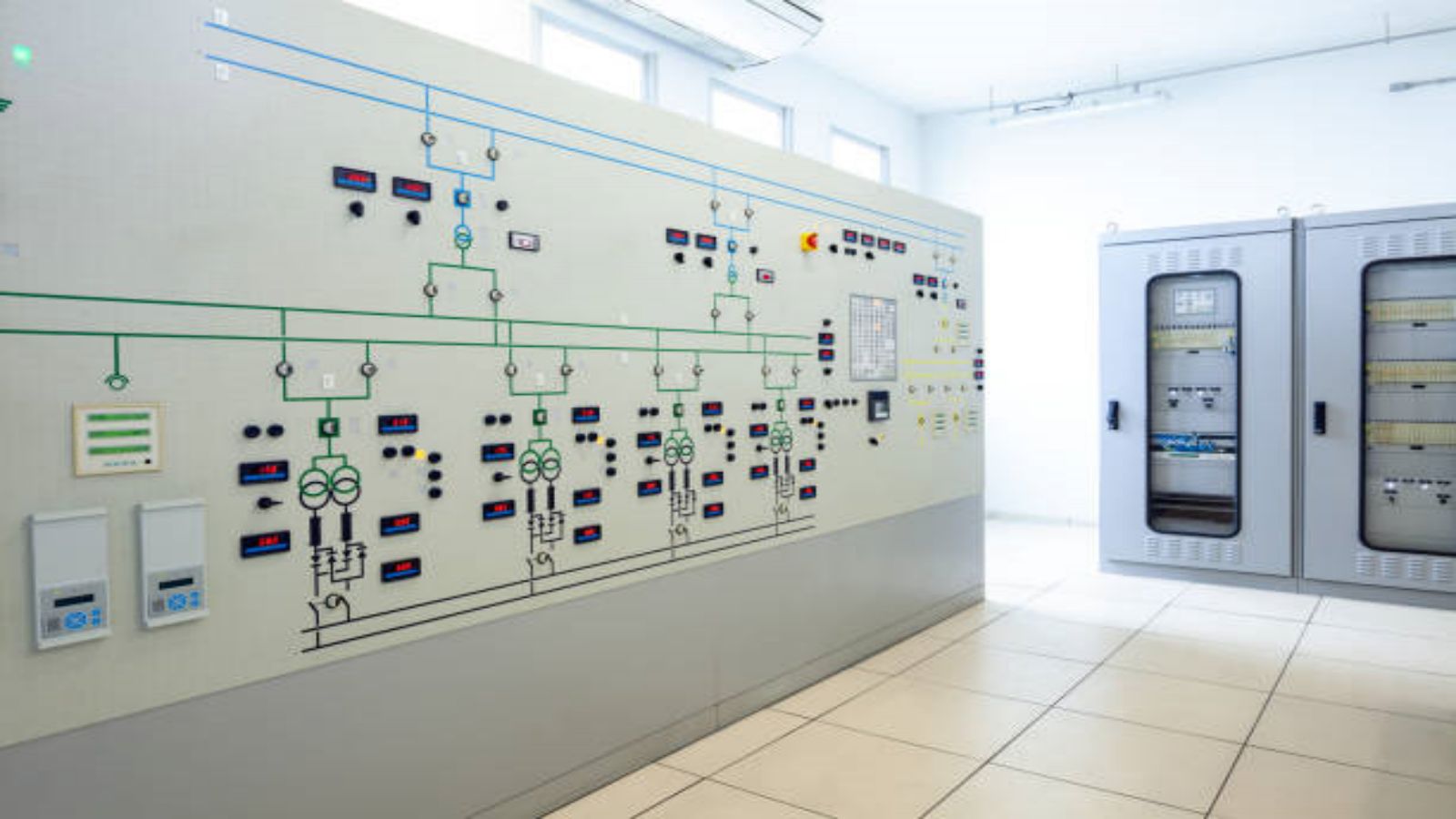

Switchgear mechanical systems play a crucial role in the efficient and safe operation of electrical power systems. Regular testing and maintenance of these systems is essential to ensure their reliability and prevent potential failures that can lead to costly downtime or even hazardous situations. In this article, we will explore various testing procedures that are employed to ensure the reliability of switchgear mechanical systems.

Visual Inspection

The first step in testing switchgear mechanical systems is a visual inspection. Trained technicians carefully examine the equipment for any signs of wear, damage, or loose connections. This inspection helps identify potential issues that may require further investigation or maintenance.

Functional Testing

Functional testing involves verifying the proper operation of various components within the switchgear system. This includes testing circuit breakers, disconnect switches, relays, and other control devices. The objective is to ensure that each component functions as intended and can effectively perform its designated task.

Insulation Resistance Testing

Insulation resistance testing is conducted to evaluate the condition of insulation materials used in switchgear mechanical systems. By measuring the resistance to electrical current flow through the insulation, technicians can identify any deterioration or contamination that may compromise the system's reliability. This test is crucial in preventing short circuits and electrical faults.

Dielectric Withstand Testing

Dielectric withstand testing is performed to assess the switchgear system's ability to withstand high voltage levels without breakdown or failure. This test applies a high voltage across the insulation for a specific duration to ensure it can withstand the expected operating conditions. It helps verify the system's insulation integrity and reliability.

Partial Discharge Testing

Partial discharge testing is used to detect and measure partial discharges occurring within the switchgear system. These partial discharges, caused by insulation defects or degradation, can lead to insulation failure over time. By identifying and quantifying these discharges, technicians can take the necessary corrective actions to prevent further deterioration and ensure system reliability.

Mechanical Operation Testing

Mechanical operation testing involves testing the mechanical components of the switchgear system, such as hinges, latches, and interlocks. This ensures that all moving parts are functioning correctly and can operate smoothly without any obstructions or excessive wear. Proper mechanical operation is vital for the reliable performance of the switchgear system.

Temperature Rise Testing

Temperature rise testing is conducted to evaluate the switchgear system's ability to dissipate heat generated during normal operation. This test measures the temperature increase of various components when subjected to their rated current for a specific duration. It helps identify any abnormal heating that may indicate a faulty component or inadequate cooling, which can lead to reliability issues.

Endurance Testing

Endurance testing simulates the switchgear system's performance under continuous operation for an extended period. This test evaluates the system's ability to withstand the rigors of regular use without degradation or failure. By subjecting the system to prolonged stress, technicians can identify any potential weaknesses and make necessary improvements to enhance its reliability.

Environmental Testing

Environmental testing involves subjecting the switchgear system to various environmental conditions, such as temperature extremes, humidity, and vibration. This helps assess the system's ability to operate reliably in different environments and ensures it can withstand any potential external factors that may impact its performance. Adequate environmental testing is crucial for the overall reliability of the switchgear mechanical systems.

Conclusion

Testing procedures for switchgear mechanical systems are essential to ensure their reliability and safe operation. From visual inspections and functional testing to insulation resistance and endurance testing, each procedure plays a crucial role in identifying potential issues and maintaining the system's performance. By following these testing procedures regularly, operators can minimize the risk of unexpected failures, extend the lifespan of the switchgear systems, and ensure the continued reliability of their electrical power systems.