Introduction to Casting Processing

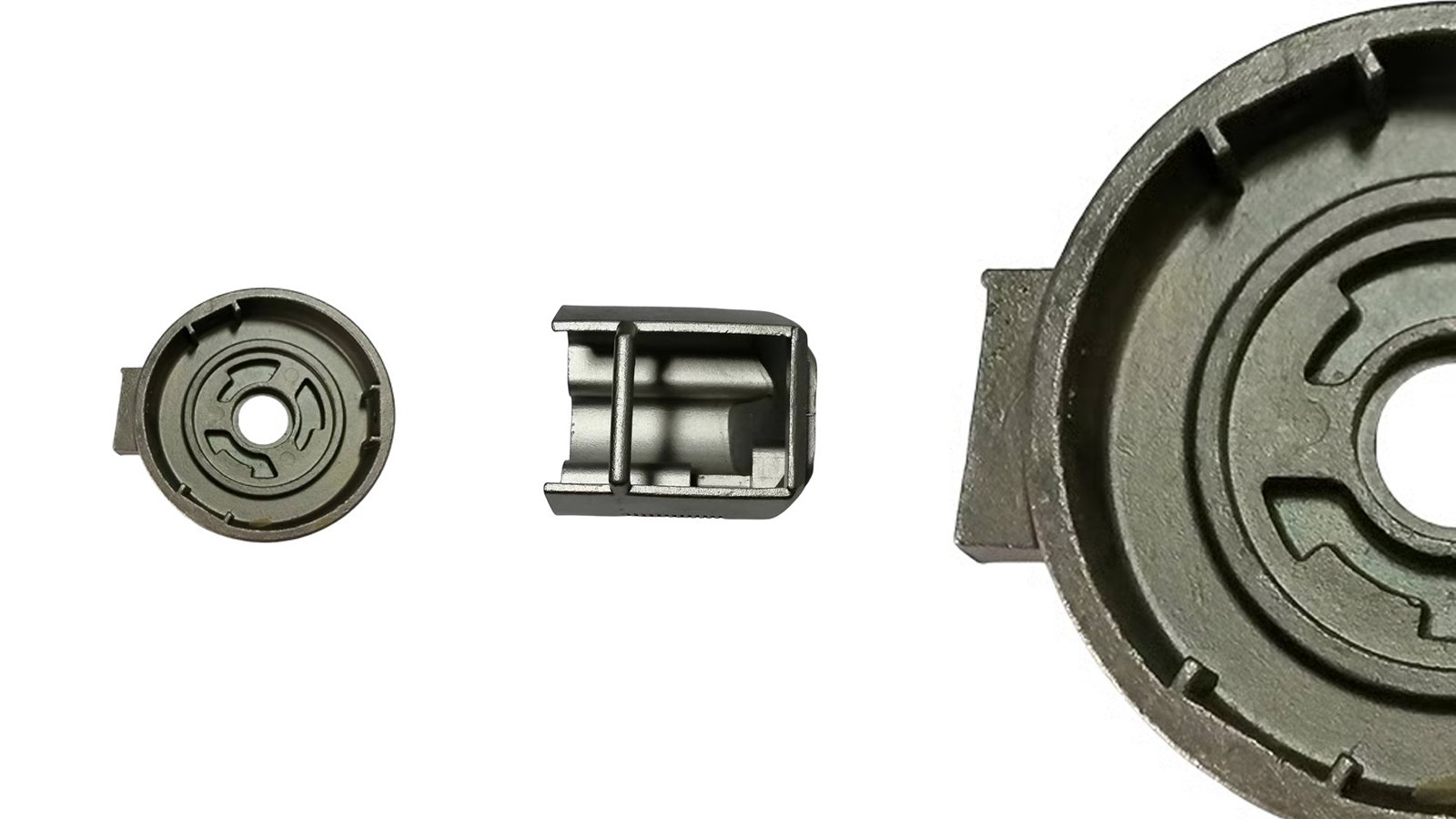

Casting is a critical manufacturing process that is widely used to produce complex parts with high precision. Innovations in casting processing have revolutionized the industry, leading to more efficient and cost-effective methods for creating high-quality components.

Advanced Simulation Techniques

One of the key

Innovations in Casting Processing for High-Precision Parts is the use of advanced simulation techniques. These tools allow engineers to predict how a part will behave during the casting process, helping them optimize their designs and reduce the risk of defects.

3D Printing in Casting

3D printing has also made significant advancements in casting processing. By using 3D printed molds, manufacturers can create intricate and detailed parts with a higher level of accuracy than traditional methods. This technology has opened up new possibilities for creating high-precision components.

Improved Materials and Alloys

Another area of innovation in casting processing is the development of advanced materials and alloys. These new materials offer superior strength, durability, and performance, making them ideal for high-precision parts that require stringent requirements.

Robotics and Automation

The integration of robotics and automation in casting processing has streamlined production processes and improved overall efficiency. Automated systems can perform repetitive tasks with precision, reducing human error and ensuring consistent quality in high-precision parts.

Green Casting Technologies

In recent years, there has been a growing emphasis on green casting technologies that minimize environmental impact. Innovations such as water-based binders and renewable energy sources have helped to make casting processing more sustainable while maintaining high precision in parts production.

Nanotechnology in Casting

Nanotechnology has also made its way into casting processing, offering new possibilities for creating ultra-precise components. By manipulating materials at the nanoscale, manufacturers can achieve unprecedented levels of accuracy in their parts, resulting in higher performance and reliability.

Real-Time Monitoring and Control

Real-time monitoring and control systems play a crucial role in ensuring the quality of high-precision parts during the casting process. By collecting data and making adjustments in real-time, manufacturers can minimize defects and optimize production parameters for optimal results.

Integration of Artificial Intelligence

The integration of artificial intelligence (AI) in casting processing is another innovative trend that is revolutionizing the industry. AI algorithms can analyze vast amounts of data to optimize casting parameters, predict defects, and improve overall process efficiency for high-precision parts.

Collaborative Research and Development

Collaborative research and development efforts between industry experts, academia, and government agencies have played a significant role in driving innovations in casting processing for high-precision parts. By sharing knowledge and resources, stakeholders can work together to push the boundaries of what is possible in the field of casting.

Quote Inquiry

contact us