Introduction to 5-Axis Machining

5-axis machining is a cutting-edge technology that allows for the simultaneous movement of a cutting tool in five different axes. This revolutionary method is transforming the way complex parts are manufactured, offering increased productivity and precision like never before.

Enhanced Precision and Accuracy

One of the key advantages of 5-axis machining is its ability to achieve complex geometries with unparalleled precision and accuracy. By allowing the cutting tool to move in multiple directions at once, manufacturers can create intricate parts with tight tolerances that were previously impossible to achieve.

Increased Efficiency and Productivity

5-axis machining offers significant time savings compared to traditional machining methods. With the ability to access multiple sides of a workpiece in a single setup, manufacturers can reduce the number of tool changes and setups required, ultimately improving efficiency and productivity.

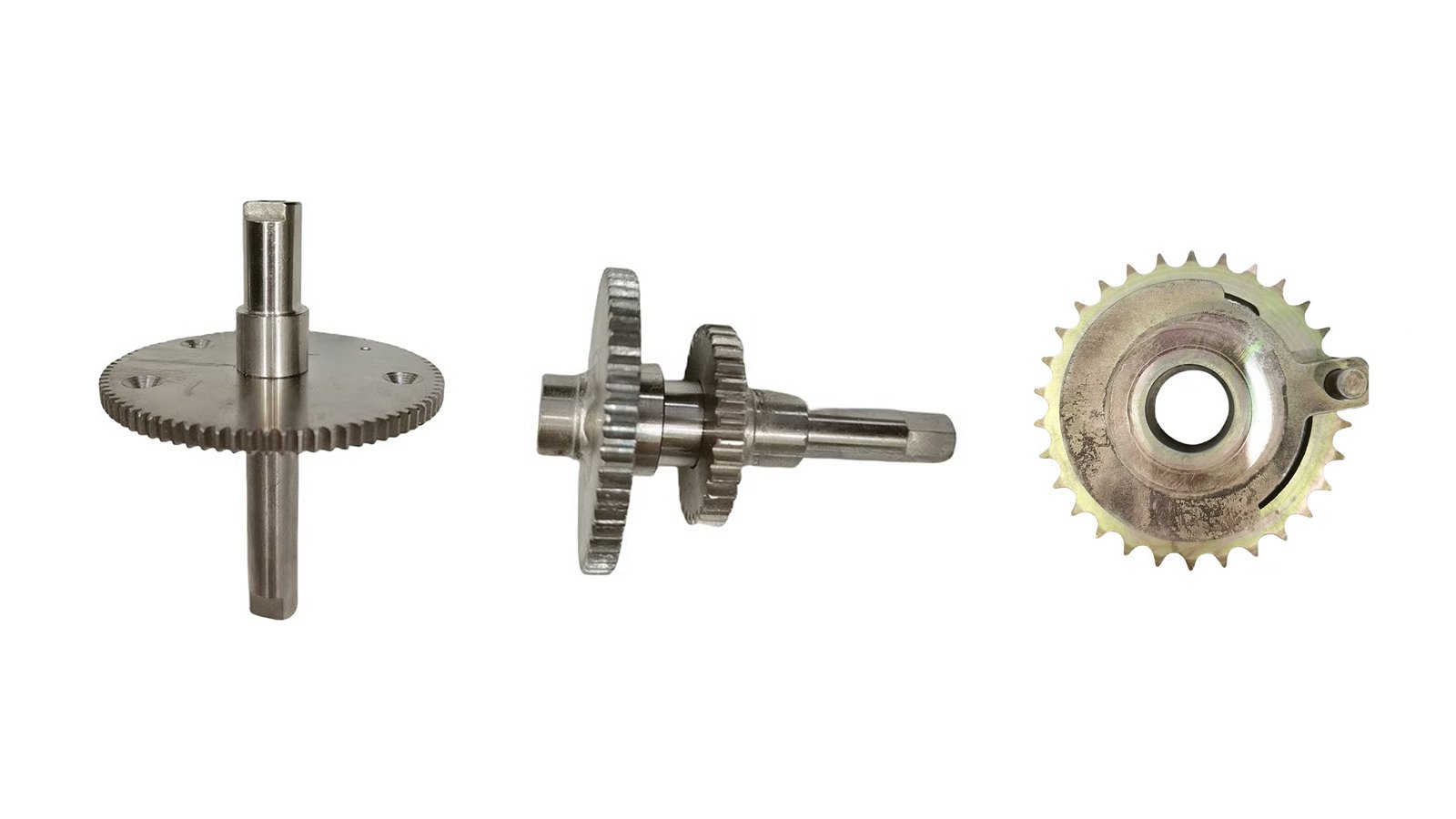

Expanded Capabilities for Complex Parts

Complex parts with intricate designs and features can be challenging to manufacture using traditional machining techniques. However, 5-axis machining unlocks a whole new world of possibilities, allowing manufacturers to create parts with complex contours, undercuts, and compound angles with ease.

Cost-Effective Manufacturing Solutions

While 5-axis machining is considered an advanced technology, it can actually be a cost-effective solution for manufacturing complex parts. By reducing the need for multiple setups and increasing efficiency, manufacturers can save time and money in the long run.

Enhanced Surface Finish Quality

The simultaneous movement of the cutting tool in 5 axes enables manufacturers to achieve superior surface finishes on complex parts. This is particularly important in industries where aesthetics and smoothness are crucial, such as aerospace or medical device manufacturing.

Improved Tool Life and Wear

5-axis machining can also lead to extended tool life and reduced wear due to optimized cutting paths and angles. This results in lower tooling costs and reduced downtime for tool changes, further contributing to the cost-effectiveness of this advanced machining method.

Maximizing Machine Efficiency

By utilizing all five axes of motion, manufacturers can maximize the efficiency of their machining equipment. This not only leads to increased throughput and faster lead times but also allows for the production of more complex parts with minimal operator intervention.

Reduced Risk of Error

With the ability to access multiple sides of a workpiece in a single setup, 5-axis machining reduces the risk of errors that can occur during part repositioning. This minimizes scrap rates and rework, ultimately leading to higher quality output and greater customer satisfaction.

Future of Manufacturing

As technology continues to advance, 5-axis machining is set to play a crucial role in the future of manufacturing. Its ability to revolutionize the production of complex parts is reshaping industries and opening up new possibilities for innovation and growth.