What is Precision Aluminum Part Machining?

Precision aluminum part machining is a specialized process that involves cutting, shaping, and finishing aluminum components to very tight tolerances. This meticulous process ensures that the final product meets the exact specifications required for its intended use in electrical systems.

The Importance of Precision in Electrical Systems

Precision is crucial when it comes to machining aluminum parts for electrical systems. Any deviation from the specified dimensions can lead to malfunctions or inefficiencies in the system. By using precision machining techniques, manufacturers can guarantee the quality and reliability of their products.

Materials Used in Precision Machining

Aluminum is a popular choice for electrical system components due to its lightweight, durable, and corrosion-resistant properties. Precision machining allows manufacturers to work with this versatile material to create intricate parts that meet the stringent requirements of the industry.

The Machining Process

Precision aluminum part machining involves several steps, including milling, turning, drilling, and finishing. Each of these processes requires specialized equipment and expertise to ensure that the final product is accurate and of high quality.

The Role of CNC Machining

Computer Numerical Control (CNC) machining plays a vital role in the precision machining of aluminum parts for electrical systems. CNC machines use computer-aided design (CAD) software to program and control the cutting tools, resulting in highly precise and consistent results.

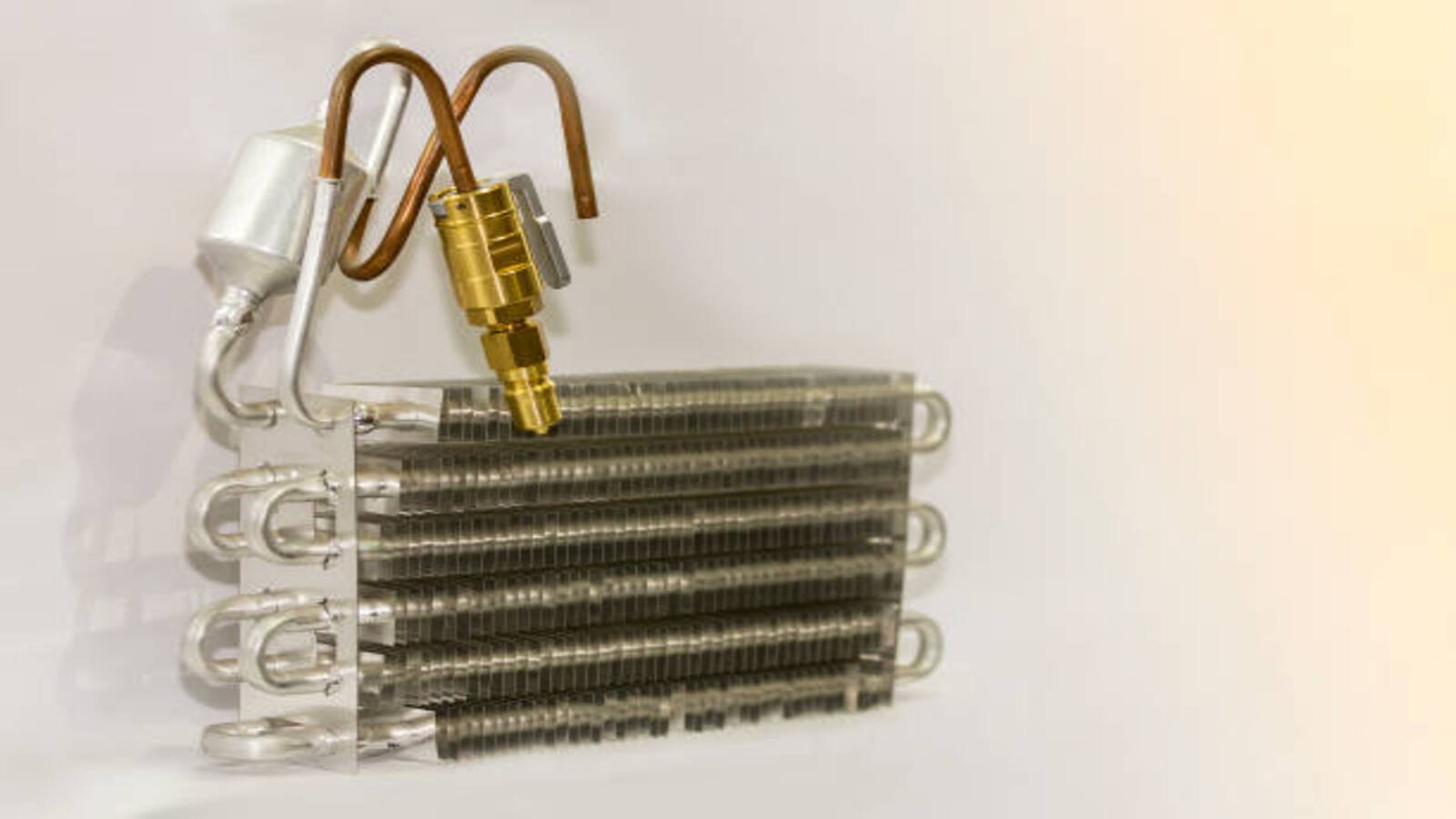

Applications of Precision Aluminum Parts in Electrical Systems

Precision aluminum parts are used in a wide range of electrical systems, including circuit boards, connectors, enclosures, and heat sinks. These components play a critical role in ensuring the proper functioning and longevity of the system.

Benefits of Precision Machining for Electrical Systems

The use of precision machining techniques in the production of aluminum parts for electrical systems offers numerous benefits, including increased efficiency, reduced waste, improved accuracy, and enhanced product quality.

Quality Control and Inspection Processes

Quality control is an essential aspect of

Precision aluminum part machining for electrical systems. Manufacturers employ rigorous inspection processes, such as dimensional checks, surface analysis, and material testing, to ensure that each component meets the required specifications.

Future Trends in Precision Machining

Advancements in technology, such as the use of automation, robotics, and artificial intelligence, are shaping the future of precision machining for electrical systems. These innovations are improving efficiency, speed, and precision in the manufacturing process.

Choosing a Reliable Manufacturer

When selecting a manufacturer for precision aluminum part machining for electrical systems, it is essential to consider factors such as experience, expertise, capabilities, and quality standards. Working with a reputable and reliable partner can ensure the success of your project and the durability of your electrical systems.

Quote Inquiry

Contact us!