Efficiency and Reliability

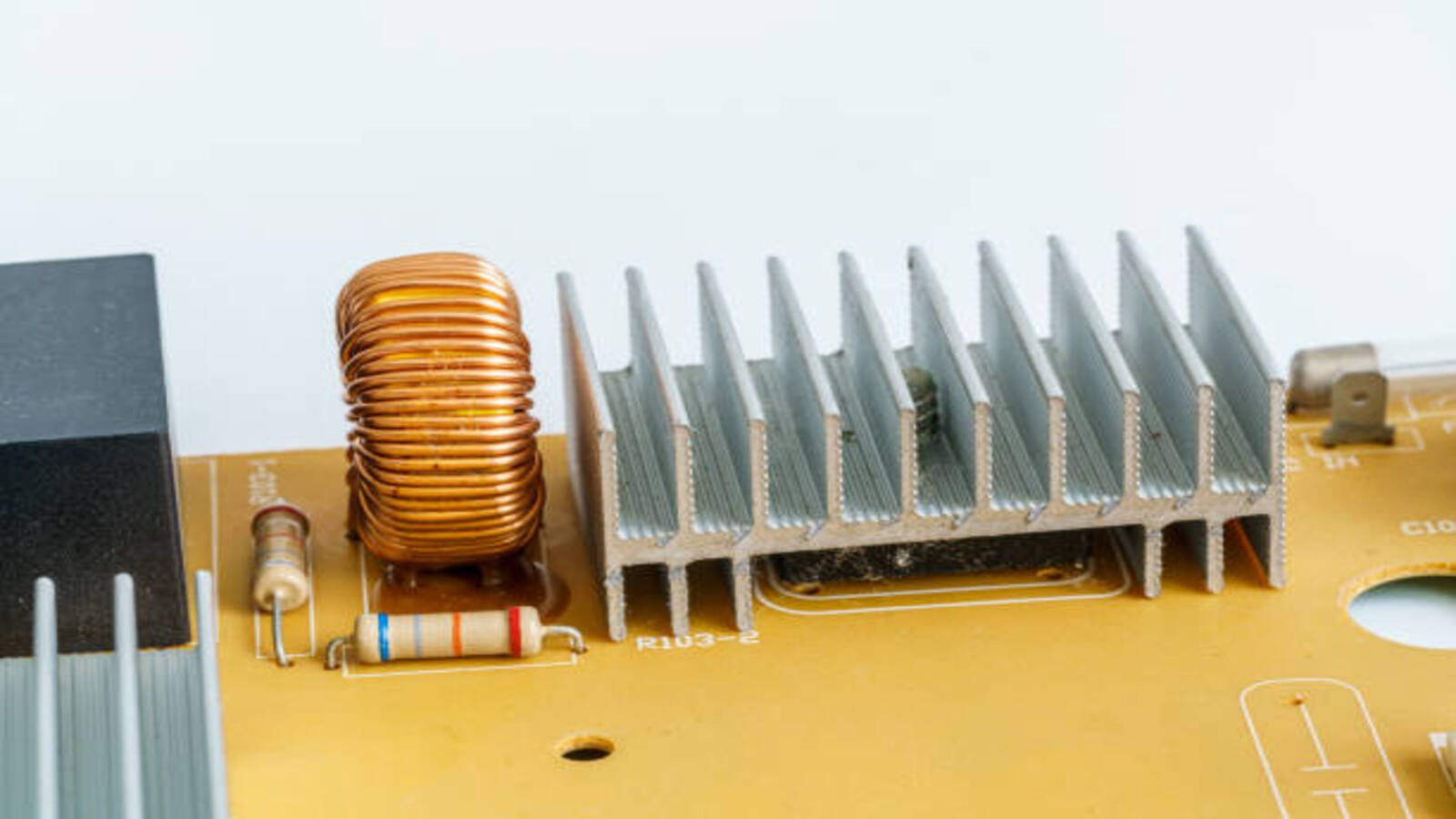

High-quality copper and aluminum parts processing for power systems is vital to ensuring the efficiency and reliability of the system. These parts play a crucial role in conducting electricity and maintaining the overall functionality of the power system.

Longevity and Durability

When it comes to power systems, longevity and durability are key factors to consider. By using high-quality copper and aluminum parts, you can extend the lifespan of your power system and reduce the need for frequent maintenance or replacements.

Optimal Performance

The performance of a power system relies heavily on the quality of its components. High-quality copper and aluminum parts are designed to withstand high temperatures, heavy loads, and other demanding conditions, ensuring optimal performance under any circumstance.

Energy Efficiency

Investing in high-quality copper and aluminum parts processing for power systems can lead to increased energy efficiency. These parts are known for their excellent conductivity, which minimizes energy loss and ultimately saves you money on utility bills.

Customization and Precision

Every power system is unique, and having the ability to customize and precision-engineer copper and aluminum parts is essential. High-quality processing facilities can tailor parts to meet specific requirements, ensuring a perfect fit and optimal functionality.

Cost-Effectiveness

While high-quality copper and aluminum parts may come at a higher initial cost, they can actually save you money in the long run. Their durability and reliability mean fewer repairs and replacements, ultimately reducing overall maintenance expenses.

Regulatory Compliance

Power systems must adhere to stringent regulatory standards to ensure safety and reliability. High-quality copper and aluminum parts processing facilities prioritize compliance with industry regulations, giving you peace of mind knowing that your system meets all necessary requirements.

Technological Advancements

As technology continues to evolve, so too does the processing of copper and aluminum parts for power systems. State-of-the-art facilities utilize the latest advancements in equipment and techniques to produce parts that are not only high-quality but also innovative and cutting-edge.

Environmental Impact

In today's environmentally conscious world, it's important to consider the impact of power systems on the planet. High-quality copper and aluminum parts processing focuses on sustainability and eco-friendly practices, helping to reduce waste and minimize the system's carbon footprint.

Industry Reputation

The reputation of a power system is only as good as the quality of its components. By investing in high-quality copper and aluminum parts processing, you can enhance the overall reputation of your system and demonstrate a commitment to excellence and reliability.

Quote Inquiry

Contact us!