Understanding High-Precision Copper and Aluminum Parts Processing

High-precision copper and aluminum parts processing is crucial for the manufacturing of electrical systems. These parts play a vital role in ensuring the proper functioning of various components within an electrical system.

The Role of Copper in Electrical Systems

Copper is widely used in electrical systems due to its excellent conductivity and durability. High-precision processing of copper parts is essential to ensure optimal performance and efficiency of the system.

The Importance of Aluminum Parts Processing

Aluminum is another commonly used material in electrical systems. High-precision processing of aluminum parts is necessary to maintain the structural integrity and reliability of the system.

Advantages of High-Precision Processing

High-precision processing of copper and aluminum parts results in accurate dimensions and tight tolerances, ensuring a perfect fit and proper functioning of electrical components.

Quality Control in Parts Processing

Quality control measures are crucial in high-precision copper and aluminum parts processing to ensure that the final products meet industry standards and specifications.

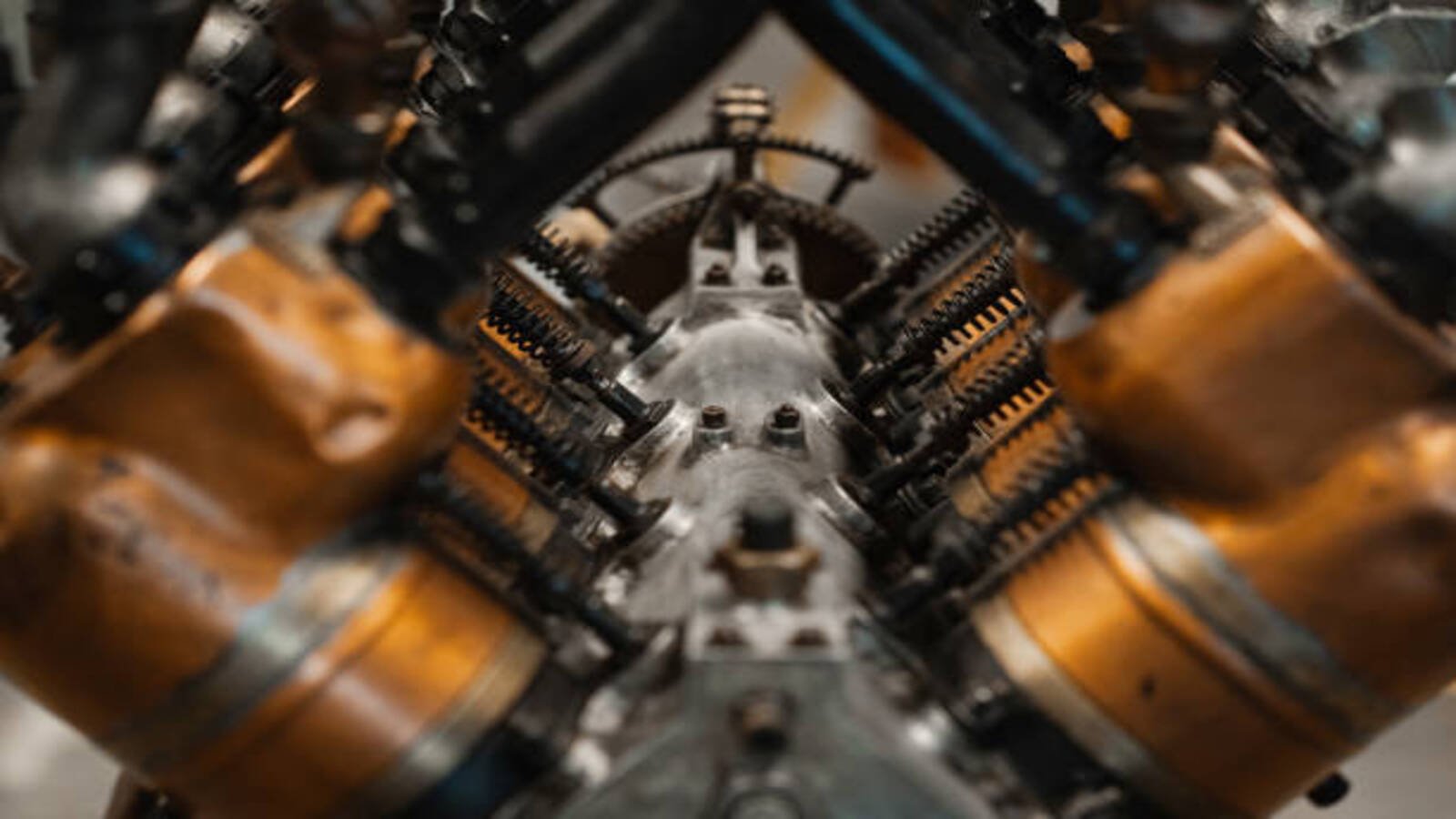

Advanced Technologies in Parts Processing

Modern technologies such as CNC machining and precision engineering have revolutionized the way copper and aluminum parts are processed for electrical systems, allowing for greater precision and efficiency.

Customization Options for Parts Processing

High-precision processing allows for customization of copper and aluminum parts to meet the specific requirements of different electrical systems, ensuring compatibility and optimal performance.

Challenges in Parts Processing

Despite advancements in technology, challenges such as material selection and machining complexities still exist in

High-precision copper and aluminum parts processing for electrical systems.

Industry Applications of High-Precision Processing

High-precision copper and aluminum parts are used in a wide range of electrical systems, including automotive, aerospace, and consumer electronics, highlighting the importance of precision manufacturing in these industries.

Future Trends in Parts Processing

As technology continues to advance, the demand for high-precision copper and aluminum parts processing will only increase, driving further innovation and improvements in the manufacturing process for electrical systems.

Quote Inquiry

Contact us!