Enhancing Durability with Aluminum Parts

Aluminum parts are commonly used in the production of electrical equipment due to their lightweight nature and exceptional durability. These parts are resistant to corrosion and can withstand high temperatures, making them ideal for a wide range of applications in the electrical industry.

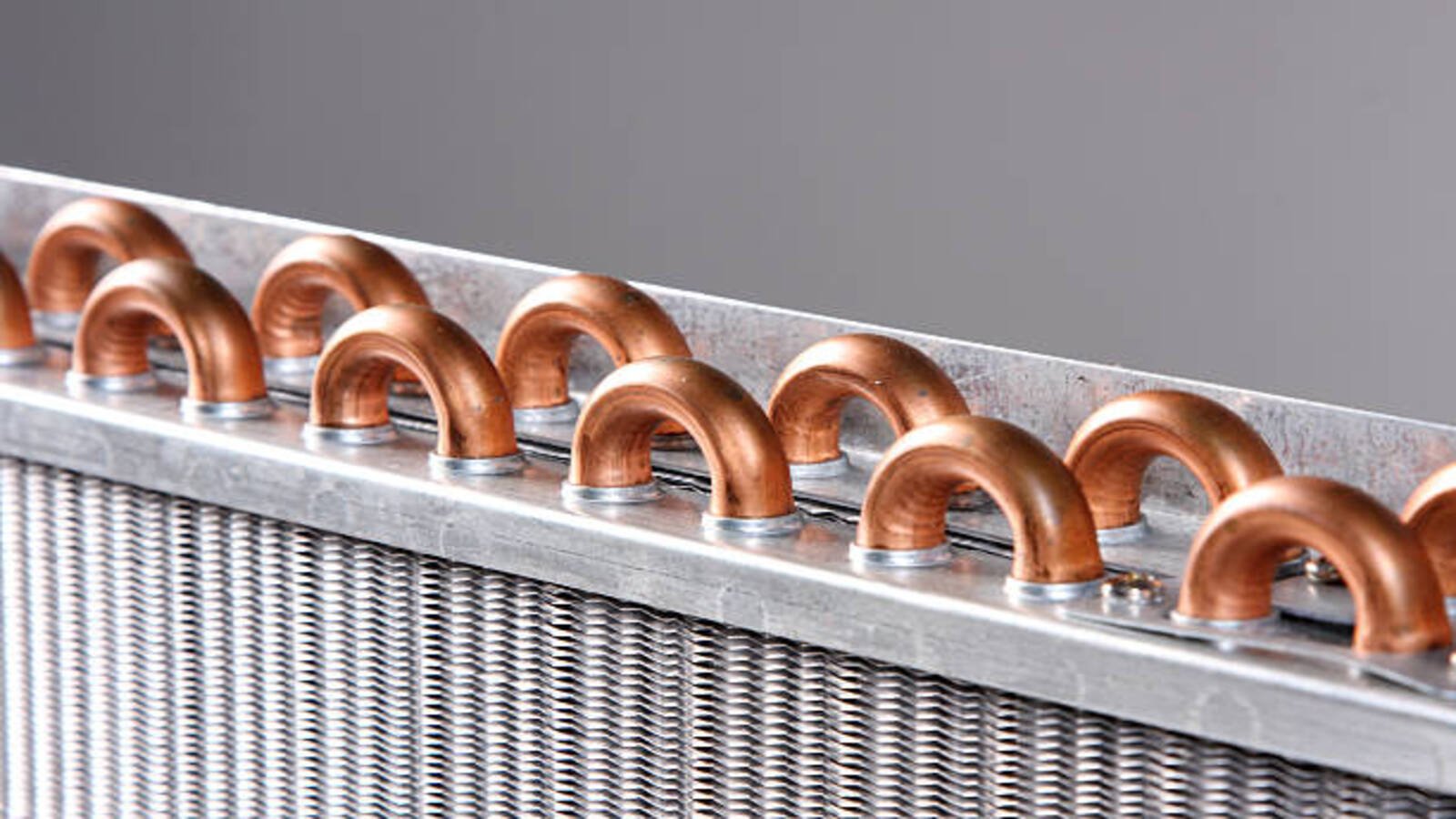

Benefits of Copper Parts in Electrical Equipment

Copper parts are known for their excellent electrical conductivity, which is crucial for ensuring the efficient operation of various electrical components. Copper is also highly durable and can be easily molded into different shapes, making it a versatile material for electrical equipment production.

Longevity and Reliability

By using durable aluminum and copper parts in the production of electrical equipment, manufacturers can enhance the longevity and reliability of their products. These parts are less prone to wear and tear, ensuring that the equipment will continue to function effectively for an extended period.

Cost-Effectiveness of Aluminum and Copper Parts

Despite their superior qualities, aluminum and copper parts are relatively cost-effective compared to other materials used in electrical equipment production. Their durability means that they require less frequent replacement, leading to long-term cost savings for manufacturers.

Environmental Sustainability

Both aluminum and copper are recyclable materials, making them environmentally sustainable choices for electrical equipment production. By using these materials, manufacturers can reduce their carbon footprint and contribute to a more sustainable future.

Resistant to Corrosion

Aluminum and copper parts are inherently resistant to corrosion, which is a crucial factor in the performance of electrical equipment. By using these materials, manufacturers can ensure that their products will remain operational even in harsh environmental conditions.

Compatibility with High Temperatures

One of the key advantages of aluminum and copper parts is their ability to withstand high temperatures without compromising their performance. This makes them suitable for use in electrical equipment that generates heat during operation.

Versatility in Design

Aluminum and copper parts can be easily molded into various shapes and sizes, allowing for greater flexibility in the design of electrical equipment. Manufacturers can create custom parts to meet specific requirements, enhancing the overall functionality of the equipment.

Resistance to Wear and Tear

With their superior durability, aluminum and copper parts are highly resistant to wear and tear, ensuring that the electrical equipment remains in optimal condition for longer periods. This reduces the need for frequent maintenance and replacement of parts.

Conclusion

In conclusion, the use of durable aluminum and copper parts is essential for enhancing the quality, longevity, and cost-effectiveness of electrical equipment production. These versatile materials offer a range of benefits, from high conductivity to resistance to corrosion, making them indispensable in the electrical industry.

Quote Inquiry

Contact us!